I like how easy it is to pick up and train others to use. It was easy to get assets and location set up and start using. Review collected by and hosted on G2.com.

I do wish that you could have more than one asset per work order Review collected by and hosted on G2.com.

Video Reviews

916 out of 917 Total Reviews for MaintainX

Overall Review Sentiment for MaintainX

Log in to view review sentiment.

We really needed help adding some order to the chaos of our heavy workflow. Sticky notes and memory were not cutting it any more. MaintainX has been so helpful in tranistioning us from reactive to preventative with our many projects we have here on property. It's clearly a software made by people who understand what it takes to maintain a facility. The implemenation had so many tutorials and support options but they're barely necessary because of how easy it is to use. Review collected by and hosted on G2.com.

Not many downsides so far to using MaintainX. The only "difficulty" is uploading all of our information so that we can have a good foundation for the software. That's not MaintainX's fault just the nature of the beast. Review collected by and hosted on G2.com.

What I like best about MaintainX is that we are able tc put in work orders anywhere and anytime and being able to label our work order at an priority or low level for not just our head maintenance team but for our wash techs as well. Quick and easy process . Also being able to have an maintainx thursday night every Thursday being able to keep up with the progress of the shop . Review collected by and hosted on G2.com.

Even though there are a few tweeks . I feel from us using in May until now there isn't reall anything to dislike you guys updated any problems we did have . Review collected by and hosted on G2.com.

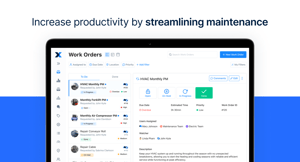

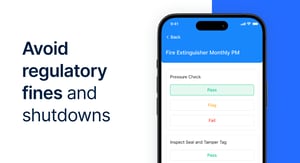

MaintainX has allowed us to streamline our old paper-based maintenance procedures by creating new digital, dynamic MaintainX procedures. Users can easily complete procedures on a device at the point of use, upload photos and provide accurate, real-time updates on work orders. Procedures are incredibly versatile and customisable and can be used for so much more than just basic maintenance activities.

Our dated excel-based asset register has now been replaced with a detailed asset management system that automatically links any Work Order with its associated asset. This provides an accurate history of any work performed for any of our assets and has saved so much time by not having to manually search through records to find the information we're looking for.

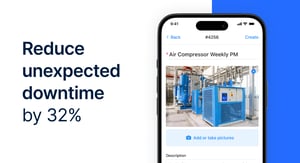

The meters feature has also now allowed us to track and monitor a wide range of readings accross our assets and facilities, providing real time visibility on equipment performance and the ability to identify negative trends before they results in a breakdown.

The MaintainX support team also provide a fantastic service. The live chat and ticketing systems put you in contact with a real person who can guide you through any troubleshooting with the system. We also have a dedicated account manager who catches up with us regularly to keep us up to date on upcoming improvements, supports system integration and answer any other questions we might have. Review collected by and hosted on G2.com.

MaintainX is a great system and the team are constantly updating it with new features and bug fixes. While its great having such support and an ever evolving system, sometimes it can be difficult to keep on top of all the new updates. Fortunately the new changelog feature now allows you access to a full version history of all changes if you need more detail. Review collected by and hosted on G2.com.

The end-user interface is the best I have ever used. The process flows they have in place make ordering parts and creating work requests a breeze. The app makes it easy for technicians to fill out work orders with detailed information. The reporting software is very powerful, allowing us to trend work and analyze work history. Customer support is always available to help with any questions or needs.

Integrating the system with Power BI for more customized reports is extremely easy and takes only a few moments.

The entire maintenance department uses the system all day, every day. It was very easy to get them to switch over from our old system when we implemented it, thanks to the app’s straightforward, no-nonsense design. Review collected by and hosted on G2.com.

With the freedom to customize the system to fit you needs makes it easy to get data entered wrong if you are not careful. more customizable permissions for users would help a great deal. Review collected by and hosted on G2.com.

its very accessible. Its a great platform to store equipment information and documents associated with the equipment. I like the layout of the panels. I use MX quite often, and find it better than the old system we would use. Review collected by and hosted on G2.com.

I find it a little annoying that I have to correctly search in "asset" or "work order" for a specific item. I would find it to type in the WO or asset number into a general search bar and then all the potential info would come up. Its almost too specific. If i get a # wrong nothing would come up. Id prefer MX suggests items absed on your search entry Review collected by and hosted on G2.com.

For the most part the product lets you create the majority of what you need pretty seamlessly. The procedure creation and templates are easy to navigate and formate to your liking! Review collected by and hosted on G2.com.

I did notice when I created a multi location multi step procedure for example our well sites its difficult to go back in and restructure the order in which these tasks are completed dependant on which route you would take, I think it would be nice to personalize how the procedures with multiple loactions and assests to be filled out and completed dependant on which user is doing this task each day. What I mean is if I go to do our "well Production" rounds I go a certain route to do them but say "john" is doing them that day and he uses a different route it would be nice to have each set to display how each user goes about completing these tasks. Not everyone does everything the exact same so I think more customization with these bigger procedures would be better. A feature for automatic calculations for certain daily rounds we do would be much appreciated because there are a few math calculations needed for correct recording of meter reads. One last thing at first how to creat templates for procedures was somwhat difficult to get started due to the lack of explanation or direction. Review collected by and hosted on G2.com.

I like that you attach parts to assets, searching assets and work orders is super easy, that I can change almost everything on the work orders Review collected by and hosted on G2.com.

you can't get the history of the asset on the iPad, you can't put more than 1 asset on a work order. I work at a production facility and we have thousands of assets on most of them we have north and south with the same assets, my guys do the 2 systems at the same time so if they do a pm for the west fan the will do the north fan at the same time, on our old system it would put the 2 on one work order but you can't on this system so my guys spend extra time having to fill out 2 work orders. I also hate that as soon as you finish a work order a new one populates and just sits there on the to-do list why can't they populate a week or 2 before they are due? Review collected by and hosted on G2.com.

MaintainX makes it easy to manage a fleet of assets and link them to meters. Automation of Work Orders can be accomplished through time or meter triggers. Each work order can include procedures (think checklists) to confirm the work is done properly.

My favorite part of Maintain X is the customer support via monthly meetings, a video library of short training clips, and a quick response chat bot. I also have been impressed by the rapid upgrades to the system and their eagerness to listen to suggestions for improvement or issue.

It was easy to get MaintainX up in a trial and we are now working toward more fully using all of the capabilities. Review collected by and hosted on G2.com.

Still having an issue with properly setting up a trigger for an Oil change. Ideally we would like to setup a trigger for 5k miles from last oil change or 6 months. So far, we have only been able to setup a 5,000 mile trigger, but that trigger immediately iterates to the next 5,000 miles for the next trigger. SO if the driver comes in 500 miles late, his next trigger will occur in 4500 miles. Hopefully the new automation engine coming next month will solve this and more. Review collected by and hosted on G2.com.

Having recently implemented Maintain X in our organization, I can confidently say that this software solution has exceeded our initial expectations. The standout aspect was undoubtedly the implementation team's professionalism and expertise. They demonstrated a thorough understanding of both the software and our specific industry needs, which made the transition remarkably smooth.

The software itself is impressively feature-rich, offering comprehensive tools for maintenance management. While the initial learning curve was somewhat steep due to the extensive functionality, the systematic pre-launch process helped our team grasp the essentials before going live. The implementation team created a detailed roadmap and stayed with us every step of the way, ensuring we were well-prepared for the launch. Review collected by and hosted on G2.com.

The software itself is impressively feature-rich, offering everything from work order management to preventive maintenance scheduling. However, the abundance of features can feel somewhat overwhelming at first, and it may take our team a few weeks to fully navigate all the capabilities confidently. Review collected by and hosted on G2.com.

After researching multiple mobile maintenance tools, our organization found MaintainX to be the most user friendly and easy to integrate. Implementation, especially specifying tools to meet our unique needs, was supported fully by our implementation engineer. We use MaintainX every day for every workorder. Customer support has been outstanding and accesible. Review collected by and hosted on G2.com.

We are beginning to utilize MaintainX as new customers. We are going through the transition from paper/pencil to a mobile application. Therefore, making the change required working through all technology issues. Our techncians are finding the application to be helpful and easy to use. Review collected by and hosted on G2.com.