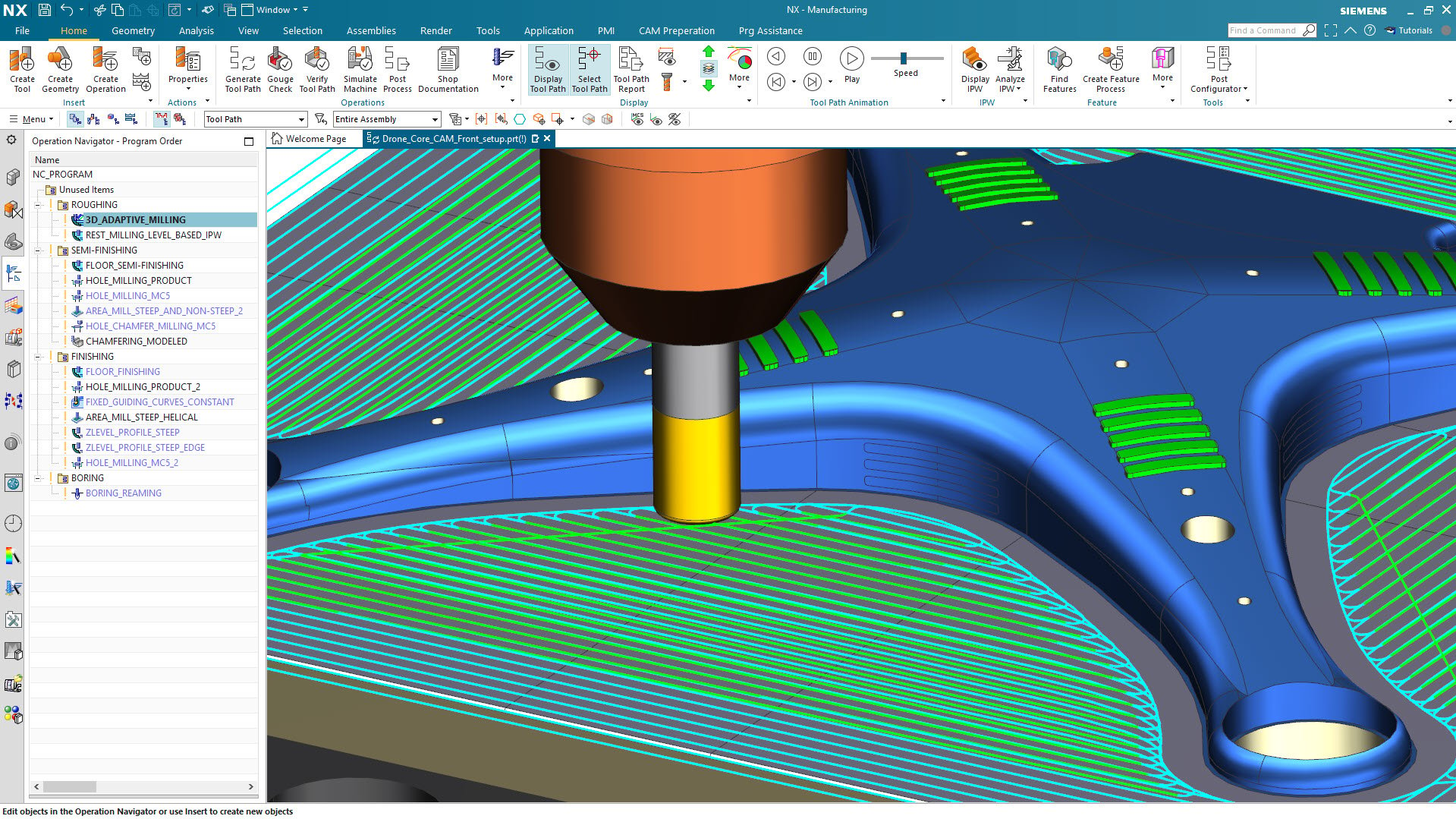

Tool path can be reached easyly on every point

Time can be saved on daily business activities.

helps a lot in customer support

Used frequently at my work place Review collected by and hosted on G2.com.

It takes more time to integrate comparing to other softwares

Implementation takes more time Review collected by and hosted on G2.com.

132 out of 133 Total Reviews for NX CAM

Overall Review Sentiment for NX CAM

Log in to view review sentiment.

There is no doubt and I hope everyone who have used this amazing software they know it as lalest and powerful computer aided manufacturing software. Mainly it's interface is very friendly and it is providing very latest technology and one more thing that is its five axis machining support and so many other important options are also available. So definitely it's a very useful for latest automation programing features, difficult design and machining and better productivity and high precision quality Review collected by and hosted on G2.com.

As per me it's high cost and steep learning curve , making it less accessible for a ll ike small business and beginners. Review collected by and hosted on G2.com.

It is a single integrated system which provides wide range of functionality, increases productivity through application specific programming, automation, integrated G-code-driven simulation. Review collected by and hosted on G2.com.

As such everything is fine but Interface can be improved slightly so that it can be more user friendly. Review collected by and hosted on G2.com.

Integration with all applications that work with 3D models (CAD, CAE, ROBOTIC..., PDM).Its shift for some time towards a smart, yet easy-to-use system. A complete CAM system covering turning, prismatic, freeform, robotic to multi-axis milling, as well as wedm and Additive manufacturing. A true digital twin, by taking the machine used in the workshop into account as early as possible. Maintaining version compatibility since the first version: customer data continuity Review collected by and hosted on G2.com.

There are still some types of machining that can be carried out using several modules. This can be a good thing, but in these few cases, the programmer may not be sure of using the module best suited to his case. SIEMENS, by creating dedicated modules rather than general-purpose modules that meet a wide range of needs, eliminates this problem and simplifies the programmer's life. Review collected by and hosted on G2.com.

Its user firendly ui & a well designed package for a software for super fast designing & other activities. Review collected by and hosted on G2.com.

Nothing, it is a good software which includes most of the required things. Review collected by and hosted on G2.com.

I appreciate NX CAM for its advanced capabilities in computer-aided manufacturing, offering comprehensive solutions for machining processes and toolpath programming. Review collected by and hosted on G2.com.

NX CAM to have a steeper learning curve compared to other CAM software, and the complexity of its features may be overwhelming for beginners. Additionally, licensing costs can be a drawback for smaller businesses. Review collected by and hosted on G2.com.

Less programming time and high part quality, thus enhancing productivity.

User friendly. I regularly use it for my offcial purpose. A good support from customer service. Review collected by and hosted on G2.com.

It takes more RAM space in the computer thus taking time to process the data. Integration & implementation with other software needs more program writing. Review collected by and hosted on G2.com.

Nx paramatric software and nx cam intigration is very helpful.

Wide range of machines support and program available.

With NX CAD and CAM integration, you can tweak models and update programs.

Model Dataloss is very low because of cad cam intigration. Review collected by and hosted on G2.com.

It's require some initial level training which is also provide by Siemens team or found helpfull tutorials.

For some VMC machine machining path can be better Optimize. Review collected by and hosted on G2.com.

The ease of the graphical interface for developers who are just starting out in the process of interacting with CAM software, is a more than representative value when it comes to minimizing the respective learning curve. Review collected by and hosted on G2.com.

In part, the minimum resources required for the installation of this type of platform will always be a very relevant item which is not only contrary to CAM platforms such as these, but also appreciable for the many existing solutions on the market. Review collected by and hosted on G2.com.

I like NX CAM over the other CAM software. It provides a classic graphical user interface with user friendly options and adequate features to perform the different manufacturing operations effectively. I like to integrate NX CAD and NX CAM makes task easy. Review collected by and hosted on G2.com.

There is bit scope for improvement for implementation of features associated to CNC lathe operations. The path optimization feature for VMC operations can be made better. Review collected by and hosted on G2.com.