Top Rated Fulcrum Alternatives

The software is excellent for managing our fabrication shop workload. What I like best about Fulcrum is that their team will listen and input our feedback! Review collected by and hosted on G2.com.

I would like to be able to talk to people on the phone, versus email. Review collected by and hosted on G2.com.

11 out of 12 Total Reviews for Fulcrum

Overall Review Sentiment for Fulcrum

Log in to view review sentiment.

Coming from a dated ERP system, Fulcrum was a breath of fresh air to our facility. As long standing users of a very common system, we were inidated with issues and mistakes that we were never able to understand and over 15 years later most of those features were left to side. I found fulcrum through a google search and hearing about it from another local fabricator. Instantly I knew this was the system for our shop and how we operate.

The biggest compliments I can give to Fulcrum is its Ease of Use and its Customer Support. We had the luxury of having Jack onboard us and through thick and thin he stayed by our side and helped us through the million roadblocks we encountered. Being able to quickly edit BOM and Routings, to Sales Order/Quotes/Inventory Auto saving, and ability to tie PDFs/drawings to a code at an instance based level is working wonders for our operations.

The introduction of using a tablet in our facility was always thought of as far into the future, but since Fulcrum is relatively user friendly, onboarding an entire shop to 1. Use an iPad 2. Use the System we have has been an quick and painless transition. The typical hiccups I was expecting were maybe an issue for one day then the team was off and using the system to about 90%. At this point its just adding the last 10% as we grow and continue to use the system to better make it fit to our standards and systems.

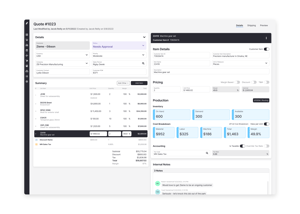

Finally being able to track setup/production/machine times instead of hand notes has also opened our eyes to see that the math we had from years previously doesnt apply to our now standardarized production. We have been able to adjust pricing and track sales to ensure a consistent marginal growth is being met along with beign able to lower costs to customers which has positevly grown relationships.

10/10 would recommend - love it - has some issues but they are willing to fix it when needed and I appreciate that they dont view their software as unchageable! We use it everyday and was integrated as easily as easily if not easier than described! Review collected by and hosted on G2.com.

Our biggest issue with Fulcrum was during implementation - data coming from our old ERP to Fulcrum was a mess. Mainly at the fault of us since we didnt use our previous to the fullest extent so alot of information was missing / we just didnt have. This creates a mind numbing few weeks during implementation trying to get everything figured out or atleast close until you can start using the system to the fullest extent.

Alot of our other issues are based just how work flow / numbers are figured in Fulcrum. We were stuck in our ways from a previous system and making the adjustment to how we think about jobs had to change.

QB intergration works but it is a bit choppy at times, work orders work for a company that does the same thing over and over again for high mix like us it doesnt work the best. Review collected by and hosted on G2.com.

This is the first Manufacturing ERP built and designed for the modern era. Fulcrum is constantly changing and growing while maintaining a culture with its customers that most companies strive for. When choosing Fulcrum, you become a part of this close-knit community where you're on a first-name basis with most of their team and other Fulcrum users. Everyone involved Is so enthusiastic about helping one another. The culture alone puts Fulcrum above Jobboss; Fulcrum's pure focus is providing a product that constantly meets your need as you expand and grow. The Platform Is great and open-ended, meaning no matter your size or specialization in the manufacturing world, you can tailor Fulcrum to meet your needs. Great for service providers to turn-key providers fulcrum can adapt and support your business. With weekly update rollouts, Fulcrum finds new ways to bring innovation to your company.

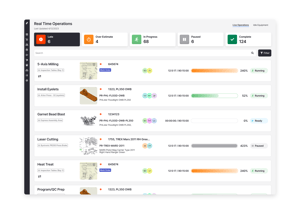

The key difference compared to other ERP Systems is that everything revolves around the Item you are producing and the machines you're running it on. Employees or companies are not tied to a particular item or device, allowing for flexible solutions while reducing redundancy. Everyone is in sync and aware of jobs, articles, revisions and changes going on with an order from your office to your shop floor.

Fulcrum should be your first choice to keep your company competitive while fostering a foundation to grow, especially in automation. Fulcrum's open API opens integration with many powerful tools, allowing basic communication improvements to complete a department's workflow automation. Review collected by and hosted on G2.com.

Honestly? Diskiles about Fulcrum are so short-lived with my company. With weekly updates and improvements, what might be a pain this week could easily be solved following an update. The platform is constantly changing, and Fulcrum is always listening to feedback. If something may not work for you in particular, reach out to your Rep, I guarantee they are either already working on an update for it or have solutions in place to help adapt Fulcrum to your needs.

Listing my current dislikes would be mute because Fulcrum today may be different from he Fulcrum tomorrow. Review collected by and hosted on G2.com.

We looked at various ERP systems as a small to medium-sized medical device manufacturer. Ultimately, we decided on Fulcrum for a variety of reasons:

- User-friendly interface and ease of use

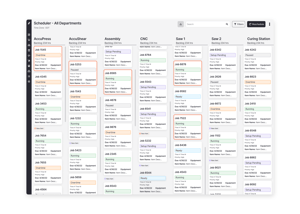

- The scheduling platform was superior to other ERPs.

- Not limited to # of users, based on the size of the company then every employee has access without additional costs (Huge for us to get entire buy-in and use from all employees top to bottom)

- Job tracking and cost analysis

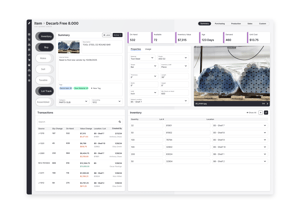

- 3D part viewer under each item

- Continually releasing updates and new features at no additional costs

Fulcrum was an easy and right choice for Qualitex, Inc. It has been a tremendous help in improving our process flow and scheduling to help ensure on-time deliveries. The cost analysis and reporting features are enormous for ensuring we maintain margins and where we can improve. The onboarding process with Fulcrum was in-depth and systematic to ensure we ran smoothly without hiccups. We integrated with QuickBooks, and while we were initially nervous about that, the Fulcrum team ensured everything went well.

I would tell anyone considering an ERP to consider Fulcrum strongly, do the demos, talk with the team and let them show you the power behind it. Review collected by and hosted on G2.com.

There isn't much not to like about Fulcrum. I've expressed my only "dislikes" to their product development team.

- A way to track tooling/fixturing costs under items & jobs (there are roundabout ways to do this, but a straightforward way would be excellent)

- When logging in and out of jobs on the job tracker, it would be nice to be able to set a stop time for when you are running lights out overnight and know when the machine will stop at a specific time (currently, you have to go manually enter the time)

- A little more flexibility in controlling the schedule where you see fit. The scheduler is very powerful and uses some form of algorithm and AI to generate the best manufacturing schedule. However, as we all know from running businesses, there is still a human element. You can turn a setting on to drag and drop the scheduling, but it can be cumbersome.

All the items about there are work-around ways to achieve what you want, but if they were more straightforward, it would save some time and give visibility. Review collected by and hosted on G2.com.

My biggest draws towards Fulcrum were the user interface and the scheduler. During my research, Fulcrum appeared to be to only MRP with an auto-scheduling feature. During our launch process, we had to tweak it a little bit, but once it was fined tuned, it began to represent what we needed on a day to day basis. We barely have to do any manual scheduling any more.

The user interface was a crucial element for me, as my workforce is primarily welders, who have little computer experience in the workplace. I needed an easy-to-use, and easy-to-learn user interface that was going to help the process. Fulcrum got it right by making a user interface on the job tracker that is click-and-play.

I also have to say during my trial runs of different software, Fulcrum had the best customer support. If you have worked with any management software before, you will discover that Fulcrum is easy to set up. Even though it's fairly easy, you have a dedicated launch manager with you every step of the way to answer questions, help overcome challenges, and help make you successful. The other MRPs on the market were hard to learn, and they didn't set you up for success.

Fulcrum is also receives updates weekly and is built on modern web-based technology. It can work on any device and is accessible from anywhere in the world. It's great for me, as I oversee my business remotely often. Review collected by and hosted on G2.com.

The biggest feature I am missing in Fulcrum is bulk editing or the ability to export all items, modify them in excel, and reimport them. Most my products are similar, but have slight variations, so when I need to make a change I have to go through one item at a time to make the changes happen. It is important during your launch process to consider how you may need to change your products in the future when building out your bill of materials, routings, and subcomponents. Review collected by and hosted on G2.com.

Pros:

Looks great

Intuitive for those familiar with computers, laid out in an easy to navigate way for those that aren’t

Fast job processing speed, and fast repeat part reorders and previous job traceability

Paperless nature make in-process print revisions easy to execute

Everything is connected, so if you have a PO#, Quote#, job#, part#, or even raw material #, you can find your way to the information you need in the system.

The inventory system is very transparent, and it has all sorts of options for note taking when it comes to inventory changes.

Customer support is spectacular.

The launch process went very smoothly for us, and having personal support assigned to us is fantastic. Any issues we come across are resolved very quickly.

The dev team is on top of it, with frequent updates, many of them being directly from customer feedback. We've been with the company less than 6 months, and at least 1 of our requests has already been implemented as a feature, along with several other changes we wanted already being in the pipes before we suggested them. Review collected by and hosted on G2.com.

Cons:

The reports section is the weakest section for us. It does not output the data in a way that can be quickly read (Pretty charts and meters), although it does give you most of what you need to generate those charts and reports. The support staff is also excellent about generating custom reports that automatically update when something the system won’t make a report for is needed.

Associating multiple jobs to one PO is more limited than we would like, but that is on the roadmap

Once a job has been started, edits to it are limited. This has already been improved by small updates since we started using it though and I have no doubts it will be fully addressed.

The fully online nature of the system means that an internet outage leaves you in the dark. Nothing to be done about this though.

The scheduling system is decent, but you need to accurately estimate production times for each part/job for it to be useful (as is expected), and the display in the schedule tab is not as easy to read as I would like. (I like Gantt charts) It does lay out upcoming due jobs in the jobs tab via sorting by production date though, and that's still loads better than how we were handling it previously. Review collected by and hosted on G2.com.

I run a 10 person cut and sew garment factory in Detroit. We're a small and bootstrapped business that needed a tech tool to scale to the next level, but hadn't found the right solution, and more importantly that fit our very small budget. Fulcrum consolidated all of our 30+ Excel sheets into one easy to use format. It keeps us organized and all on the same page. It also saved a ton of time from entering data and cleaning data. My staff was all tracking production times on their phones and with pen and paper before manually entering it into Excel at the end of each day, now it's all done in real time via iPads that everyone keeps at their work station.

The Fulcrum team is all amazing and very accessible even a year after implementation to help us with all issues that arise. I couldn't recommend it more for small manufacturers. Review collected by and hosted on G2.com.

Sometimes there is a little lag between data entered and when it shows up in the system, which throws my shop staff off when everything isn't lining up right away, but it almost always corrects in time and matches up. Overall I'm very impressed how little issues we have, we just need to resync data on occasion. Review collected by and hosted on G2.com.

I think the best thing about Fulcrum is its overall simplicity and layout, as well as frequent feature updates and support. At times this simplicity can be limiting, but the team is pretty good about taking in recommendations, and updates are both regular and useful! Having a specific onboarding team member there by your side during implementation and then a success manager to help with questions after the fact is amazing, and easily the best part of Fulcrum when compared to other MRPs which just leave you to figure it out yourself. Review collected by and hosted on G2.com.

At times, the limitations mentioned before can be a bit of a block. I'd say 80% of businesses that run conventionally will never have issues with Fulcrum, but our particular setup is fairly complex and constantly changes thus leading to some issues that we have to address ourselves. Review collected by and hosted on G2.com.

FulcrumPro creates an excellent solution for paperless shop floor management. Using tables critical data is collected for the manufacturing process Review collected by and hosted on G2.com.

Some of the back end user interface is cumbersom at times Review collected by and hosted on G2.com.

Fulcrum has allowed us to significantly grow our business through timely and accurate quotes, shop-wide communication and on-time delivery. Review collected by and hosted on G2.com.

Every so often, we discover a "bug" as they are continually improving their software. These are quickly remedied and we rarely skip a beat. Review collected by and hosted on G2.com.

We have been implementing and using Fulcrum at our manufacturing firm in New Zealand since December 2020. Our company has a headcount of 25, half spread across sales, marketing, engineering and admin, and the remainder as production team members working on the shop floor. We’ve doubled our headcount in the last 12 months, and are looking for tools to help us scale more rapidly. We believe that looking back in 5 years from now, Fulcrum may well be the tool that had the biggest effect on our growth.

The launch team that we were paired with from day one of our implementation were instrumental in our successful launch. We had weekly video calls with them to help us understand the basics, they answered our myriad of questions and they helped us with preparing the data we needed to get Fulcrum live, but it’s also fair to say the implementation did take us a lot longer than first anticipated. A lot of these delays came down to the data set that we had. Our BOM’s were lacking clarity, and the process of getting the data into Fulcrum was not very streamlined. More details about this are in the section below.

We rolled out a staged launch of Fulcrum in our business, with key components being switched over from the outgoing systems over the course of around 6 months. First Inventory management, then Jobs, and then lastly the Job Tracking component that is utilised on the shop floor by our production team members. We also had to complete a full stocktake on the day Job Tracking went live, to ensure the system had all the right information for scheduling.

We are still getting our team completely up and running on Fulcrum’s automated schedule, but once we do, we believe that the superhuman knowledge of the Scheduler understanding every product, sub-component, machine, operation, staff member, inventory level, lead time and many more data points will allow us to scale our manufacturing at a rate not possible via anything else we’ve seen in the market. Review collected by and hosted on G2.com.

We have a good relationship with the key staff at Fulcrum. From their implementation team, right through to their CEO. This is because their company is young, the product is still maturing, and they are experiencing the same growing pains that we are - and so with that, we have a lot of communication with them regarding the product, and the resolution of the problems or questions that we raise.

We believe the core of the product is sound. The Scheduler is the magic sauce, and it works. But the user experience within the product from onboarding right through to day-to-day usage of the system by our team has room for improvement. It is also accurate to say that they *are* improving it. The product has been refined incrementally over the 10 months we have been using it and we hear that the pace of improvement will only increase into the future as they scale up their engineering team.

Regarding the setup process. We have less than 2000 unique item numbers in our company, spread across 10 or so core products. Unfortunately, our previous inventory system kept these as flat BOM’s, so adding the data to tree those products for Fulcrum to understand took us a lot of time. Being based in New Zealand also didn’t help, as we needed a US-based Fulcrum team member to upload our data set each time we had another version to test. Due to the timezone differences, this was usually just a once per day operation whereas if the upload was possible via a user-facing page, we believe we could have been testing uploads multiple times per day. I wouldn’t be surprised if Fulcrum launch their own upload tool in the future just to take that load off their launch teams.

There are a lot of other unique “Fulcrum characteristics” in the platform, that we’re not used to experiencing in other more mature SAAS platforms, but thankfully these are decreasing weekly, and we look forward to the system eventually being simple, clear and robust enough for all our staff to understand and use without too much oversight.

Finally, the lack of quality user documentation due to the rapidly evolving platform also hindered our onboarding timeline as most information was learnt during our weekly meeting. While the meetings were good and I understand the reason behind the lack of docs so far, I was pleased to recently hear that user documentation is high on their priority list. Review collected by and hosted on G2.com.