For a long time, it was a point of pride to say your product was Made in America. But with the global economy shifting, that’s becoming less and less practical from a business standpoint.

The internet has opened us up to a world of new opportunities. It’s made it easier to connect with people around the world and broadened our views. It’s also become a lynchpin in the growing global economy. With the supply chain industry booming, there’s an increased need to go global to stay competitive.

Faster turnaround times, access to more customers, and better business insights are all incentives to take your business abroad. Opting for supply chain planning software can help achieve better insights and plan and streamline the process, forecast supply and demand, and tackle any supply chain issues before they arise.

According to recent data on supply chain statistics, 48% of supply chain and transportation executives say they are experiencing the need to reevaluate warehouse locations due to the shifting trade patterns impacted by the U.S. economy. When it comes to going global with your business, the right time is now.

What is a global supply chain?

A global supply chain is a worldwide network where companies purchase or use goods manufactured overseas. Global supply chains require a variety of people, information, processes, compliance, and resources to run smoothly.

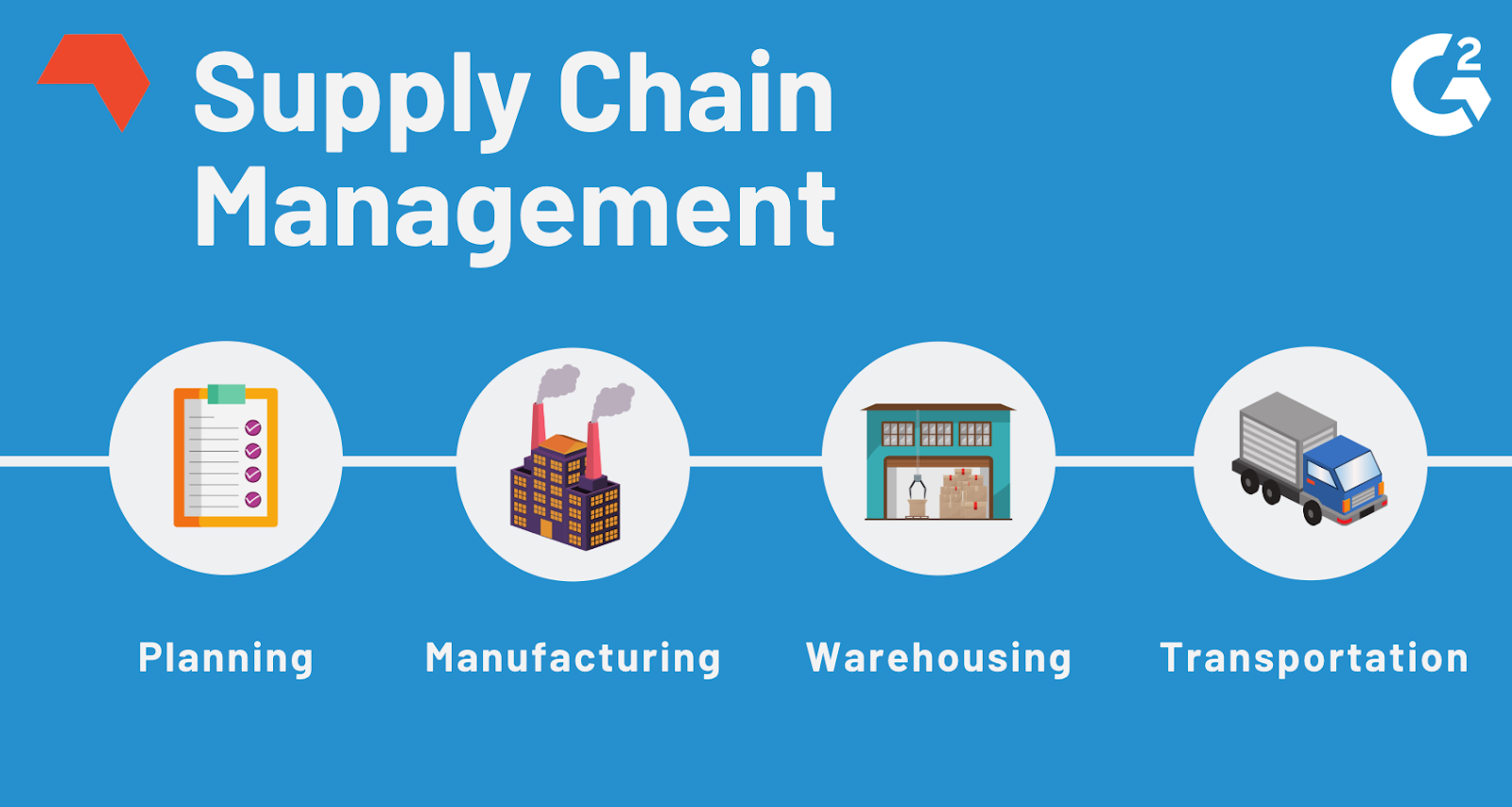

Everything from the creation and production of products to the handling and distribution of materials, to the shipping of finished products to the customer, is part of the global supply chain process. The typical journey through a global supply chain is comprised of four different stages: supplier, manufacturer, distributor, and customer.

Benefits of a global supply chain

As companies expand and look to reach new markets or even increase the number of products they create, the need for a global supply chain becomes more important. By expanding your reach internationally, you can produce the same products at a cheaper cost, reach new customers, and expand the variety of products you can create.

- Increased efficiency: A global supply chain allows companies to source materials and products from across the globe. This leads to cost savings and increased efficiency in production. Companies also have the option to choose locations with the most optimal and cost-effective production.

-

Greater flexibility: Companies adjust their production and sourcing strategies to respond to changing market conditions. For example, they can quickly shift production to a different location in response to supply chain disruptions, providing greater flexibility.

- Greater access to resources: It provides access to a wider range of resources, such as raw materials, talent, and expertise. If the resources in a particular country are expensive, a company can source these resources from elsewhere. This can help companies to innovate and produce higher-quality products.

- Increased market reach: Companies can expand their reach by accessing new markets and customers worldwide. This can help to increase sales and revenue while reaching a new set of audience.

- Risk diversification: It helps to diversify risk by spreading production and sourcing across different locations. This reduces the risk of disruptions due to natural disasters, political instability, or other factors affecting one area.

Want to learn more about Supply Chain Planning Software? Explore Supply Chain Planning products.

Global supply chain issues

Global supply chain issues were prominent during the COVID-19 pandemic, such as the movement of goods, materials, and services across borders. The production, distribution, transportation, and delivery across borders were shut off, thereby causing delays and termination of production.

Common global supply chain issues:

- Trade tensions: Trade barriers, tariffs, and other protection measures can disrupt the flow of goods and increase trade costs, making it harder for businesses to source materials and products from other countries.

- Cybersecurity and data breaches: Cybersecurity attacks and data breaches can compromise the security and integrity of supply chain data, leading to delays and loss of trust between partners.

- Logistics and transportation disruptions: Disruptions and capacity constraints in shipping and air freight can cause significant challenges for businesses moving goods worldwide.

- Natural disasters and climate change: Natural disasters like hurricanes, earthquakes, and wildfires can disrupt global supply chains by damaging infrastructure, disrupting transportation networks, and causing production and delivery delays.

Global supply chain issues are complex and interconnected, requiring businesses to be proactive and adaptive in their strategies to mitigate risks and ensure resilience in their supply chains.

Tips for managing a global supply chain

Understanding what makes up the nuts and bolts of a global supply chain is nothing if you don’t know how to manage one. Each of these five tips is designed to help you avoid the common mistakes associated with supply chain management.

1. Do your research

Creating a global supply chain isn’t as easy as choosing a location and getting started. There are a lot of geopolitical and logistical implications that can slow you down. Before you choose a location to expand your business into, be sure you understand the local laws surrounding business expansion and supply chain management. Understanding the supply and demand thoroughly is part of the research process to ensure smooth operations.

2. Stay compliant

Expanding globally means you’ll need to be more vigilant than ever when it comes to your compliance. Knowing the risks associated with global supply chain expansion and having a plan to prevent issues is important.

Some companies will employ the help of a Chief Compliance Officer, while others use software solutions like operational risk management software to streamline the process. Whichever you choose, compliance with both local and international law is the most important part of the process.

Tip: Interested in learning more about operational risk management software? Check out these reviews from G2 users.

3. Understand the risks

There will always be risks when it comes to building a business. But taking things global presents a slew of new challenges you might not be aware of. One of the most common mistakes someone can make when expanding their operations globally is not accounting for the risks involved.

Supply-side risk

A supply-side risk happens on the production end of things. This can include limited access to raw materials needed to make products, extended wait periods on those raw materials, or a sudden increase in price due to local currency fluctuations. When you take your operation global, many factors are out of your control. Always be cautious and plan for situations like the ones mentioned here.

Demand-side risk

A demand-side risk happens once a product is finished. One of the most common demand-side risks comes from the demand for the product itself. Sometimes you produce more products than people who want them, leaving you with unwanted goods on your hands.

On the other hand, you might produce too few items and be met with high customer demand. This is often very hard to forecast, which means the chances of you running into this issue are very high.

Other risks

There are countless other risks at play that don’t fall under the compliance side of your business. A major weather event could disrupt your shipping and distribution plans, labor law changes could interrupt your workflow, and geopolitical politics could sour relationships between nations. Expect the unexpected and be prepared to change plans, because there’s no end to what might go wrong.

4. Perfect the process

There’s no use in expanding globally if you don’t have the basics down. Supply chain management is a complicated business that requires keen attention to detail. Your supply chain includes partners working together to provide the raw materials for manufacturing, warehouse layout and storage, and distributors working on getting the products into the hands of the customer.

Not only is the process itself a challenge, but maintaining the low cost and quality of products while scaling is important. The wrong type of material can compromise the structural integrity of a car, or the wrong ingredient can make food products unsafe to eat. Ensuring that your process to perfected can save you the trouble of a lawsuit, recalled products, or worse.

5. Optimize with software

Managing the different teams, vendors, and processes involved with global supply chain management can be tough. That’s why many people turn to supply chain planning software to help streamline their workflow.

Supply chain planning software allows you to:

- Manage vendors both locally and internationally

- Help plan, source, and organize the different parts of a supply chain

- Provide tools for demand planning, inventory planning, replenishment planning, order planning, and production planning

And while supply chain planning software can’t take care of every small detail, it can help you automate many tasks that would otherwise be exposed to human error. This can help minimize overall risks, speed up the production process, and keep everything running smoothly.

Supply chain planning software

Along with the tips mentioned above, choosing a supply chain planning software will help you ensure efficient operations. A planning software will help inventory and order planning, facilitate delivery, and prioritize shipments, among other benefits.

Every company has different needs, such as logistics, warehousing, or transportation. Choosing the right software for your company will help optimize the process. Here is a software grid to help choose among the best players in the market.

Supply and demand made easier

There’s nothing easy about running an international business, but there are ways to lessen the burden along the way. Doing the work smarter and using technology to your advantage can help you outpace your competitors and reach more customers, with better products, faster than ever.

Warehouse management is an important part of the global supply chain, but without warehouse management software, it becomes difficult to store products and improve warehouse operations.

This blog was originally published in 2019. The content has been updated with new information.

Lauren Pope

Lauren Pope is a former content marketer at G2. You can find her work featured on CNBC, Yahoo! Finance, the G2 Learning Hub, and other sites. In her free time, Lauren enjoys watching true crime shows and singing karaoke. (she/her/hers)