What is materials management?

Materials management is a function of supply chain management that focuses on planning and organizing necessary company materials. This includes controlling the movement of materials, ensuring essential materials are available for manufacturing, and producing accurate and reliable final products.

Materials management is just one aspect of the entire supply chain management process. As supply chain management moves products from supplier to customer, materials management takes care of the in-between, where important resources are identified, stored, and used throughout the process.

Managing raw resources, turning those into products to meet customer demand, and distributing these products efficiently can be extremely time-consuming and tedious. This is why some companies utilize supply chain management software to automate the process. Supply chain management software allows a company to create comprehensive workflows, track and optimize costs, and access company information anytime, anywhere.

Materials to manage

The main materials that companies manage can be divided into two categories: direct and indirect materials. Understanding the difference between these materials can allow companies to gain better insight into their materials inventory and effectively allocate time, resources, and budgets.

Direct materials are materials used in the manufacturing process and are a direct piece of the product. These materials are included in the final product that gets distributed to customers. For example, in the production of clothing, fabric would be considered a direct material. Direct materials are a bit easier to organize and budget because the amount of material directly correlates with how many product units are being created.

Indirect materials are also used and needed in the manufacturing process but are not pieces of the product itself. They would usually not be included in the final production costs. In the production of clothing, a sewing machine would be considered an indirect material. Indirect materials can also include cleaning supplies, adhesives, and employee protection equipment like gloves and helmets. Because indirect materials consumption is not as easy to attribute to a specific amount of products, the budget would usually be filed under manufacturing overhead costs.

Types of materials management

Materials management can be broken down into five different types where materials are organized and allocated. These types are needed to ensure that materials are efficiently managed and that the entire creation, production, manufacturing, and distribution of a product is successful.

- Materials requirements planning: This is all about maximizing the use of materials while finding ways to minimize expected production costs. Some companies use materials requirements planning to explore various materials management methods like the just-in-time (JIT) method, where materials are ordered only as needed. Materials requirements planning is essential, and the risks involved with using methods like JIT should always be considered.

- Quality control: Decisions regarding the quality of products are conducted at this stage. This includes checking product accuracy, durability, and overall performance. Companies prioritizing quality control will ensure that all items leaving company grounds are in good condition and meet customer requirements and expectations.

- Flow and supply: Focus on how materials move inside and outside the organization. The flow of products should be controlled so there are no discrepancies in inventory counts and supply can be replenished effectively. When supply is maintained effectively, companies have a lower risk of facing the challenges that come with a surplus or shortage.

- Purchasing: Profits aren’t as sweet when income is not budgeted efficiently. The purchasing stage of materials management focuses on where money should be allocated to maximize profits while maintaining operational efficiency. This includes outsourcing supplies and purchasing raw materials ethically and economically.

- Inventory control: Inventory control focuses on regulating the items in stock. These items include raw materials, purchased goods, and final products ready to be sold. The way these units are controlled varies depending on unique company needs, but all inventory control methods should streamline the way materials flow in production and increase optimization.

Benefits of materials management

With a successful materials management plan in place, companies can ensure that all resources necessary for production are accounted for and made available. The benefits outline just what materials management can do to help a company run more productively, both in and out of the production and manufacturing process.

Effective materials management will allow a company to:

- Reduce waste by organizing supplies, budgeting for essential items, and allocating resources effectively to minimize the chances of excess materials.

- Decrease unnecessary costs by understanding what is absolutely needed to create a good or service. Depending on the inventory management method of choice, a company can ensure that only the most necessary materials are budgeted and ordered. This will provide more opportunities for saving funds instead of purchasing useless items that take up inventory space.

- Ensure material availability by managing all materials as they move through the production workflow. By decreasing unnecessary costs, these budgets can be utilized to guarantee that the actual materials needed are always available, organized, and made ready for use.

- Improve employee productivity by making all production resources available to team members. Failing to manage materials can create disruptions in the timing of a project. Adequate materials management will keep things running smoothly, employees aware of expectations, and costs of fixing issues down.

- Increase customer satisfaction by creating reliable products quickly. When materials are being managed effectively, production and distribution run very smoothly. A well-running supply chain means products are being delivered to customers more efficiently than ever. Being more productive and reliable than competitors creates customer satisfaction and loyalty.

How to create a materials management strategy

Supply chain management is all about planning, allocating resources, and creating a successful good or service that makes customers happy. Materials management plays a huge role in ensuring that communication within the supply chain is accurate and streamlined. A successful materials management strategy should detail exactly what is needed to produce a product, how much of it is required, and when. This strategy will outline product life cycle requirements and adjust those needs as supply and demand fluctuate.

To start implementing a materials management strategy, follow the six steps below:

- Identify company goals. A materials manager should work closely with a supply chain manager to understand the objectives for production. These goals will help a materials manager ensure that all the materials necessary to meet those goals are available. If not, any inconsistencies can be addressed as soon as possible.

- Gather data. There is no such thing as too much information when it comes to materials management. Collecting data will uncover any discrepancies in the number of materials used in production. Identifying and adjusting these issues before creating a strategy will help free up some resource budgets that can later be allocated more successfully.

- Keep constant stock. As things continue to move within inventory, ensure that stock is being continuously tracked. Keeping a close eye on materials already in rotation decreases the chances of purchasing unnecessary items and creating more waste.

- Forecast customer demand. The most important step in creating a materials management strategy is demand planning. Demand planning gives companies insight into what is required to obtain materials and create a good or service. Using historical demand data will help prepare for predicted customer needs and manage materials accordingly. This process can be automated using demand planning software.

- Train employees. A good plan is nothing without those who carry it out. Before implementing a materials management strategy, ensure that all employees understand what is expected of them and their roles in the big picture of production.

- Utilize inventory management techniques. Many companies use inventory management techniques when creating a materials management strategy. As mentioned earlier, the just-in-time (JIT) method is popular for those who hope to minimize costs. Other methods include the economic order quantity (EOQ) model, the ABC analysis, the first-in-first-out (FIFO) method, and the last-in-first-out (LIFO) method. The right inventory management technique can differ for companies depending on whether they provide perishable items or organize items by importance.

Materials management best practices

Materials management has many moving parts, so perfecting it can be especially tedious. Here are some best practices to keep in mind when managing materials in the production process and the overall supply chain:

- Conduct quality control checks. Quality control checks are necessary to ensure that every product being distributed is up to par with market standards. Materials management can be useful in guaranteeing that all aspects of a product, whether directly or indirectly, are good enough to be used in production.

- Maintain open communication. While materials are just one aspect of the entire supply chain, they’re not exempt from working as a unit. Managing materials also means maintaining open communication with other teams within the supply chain who also work to complete the puzzle of a successful product.

- Outsource trustworthy suppliers. Most of the raw materials are not made in-house. Ensure that all outsourced resources come from reliable suppliers who understand and comply with the organization’s goals and objectives.

- Identify opportunities for improvement. When attempting to optimize and make changes in materials, the best people to consider are those who work with those materials daily. Consult with production employees in decision-making and strategizing, and ask for their honest opinions on areas for improvement.

- Automate the process with software. When it all gets a little overwhelming, consider implementing software to automate strenuous processes.

Materials management vs. supply chain management

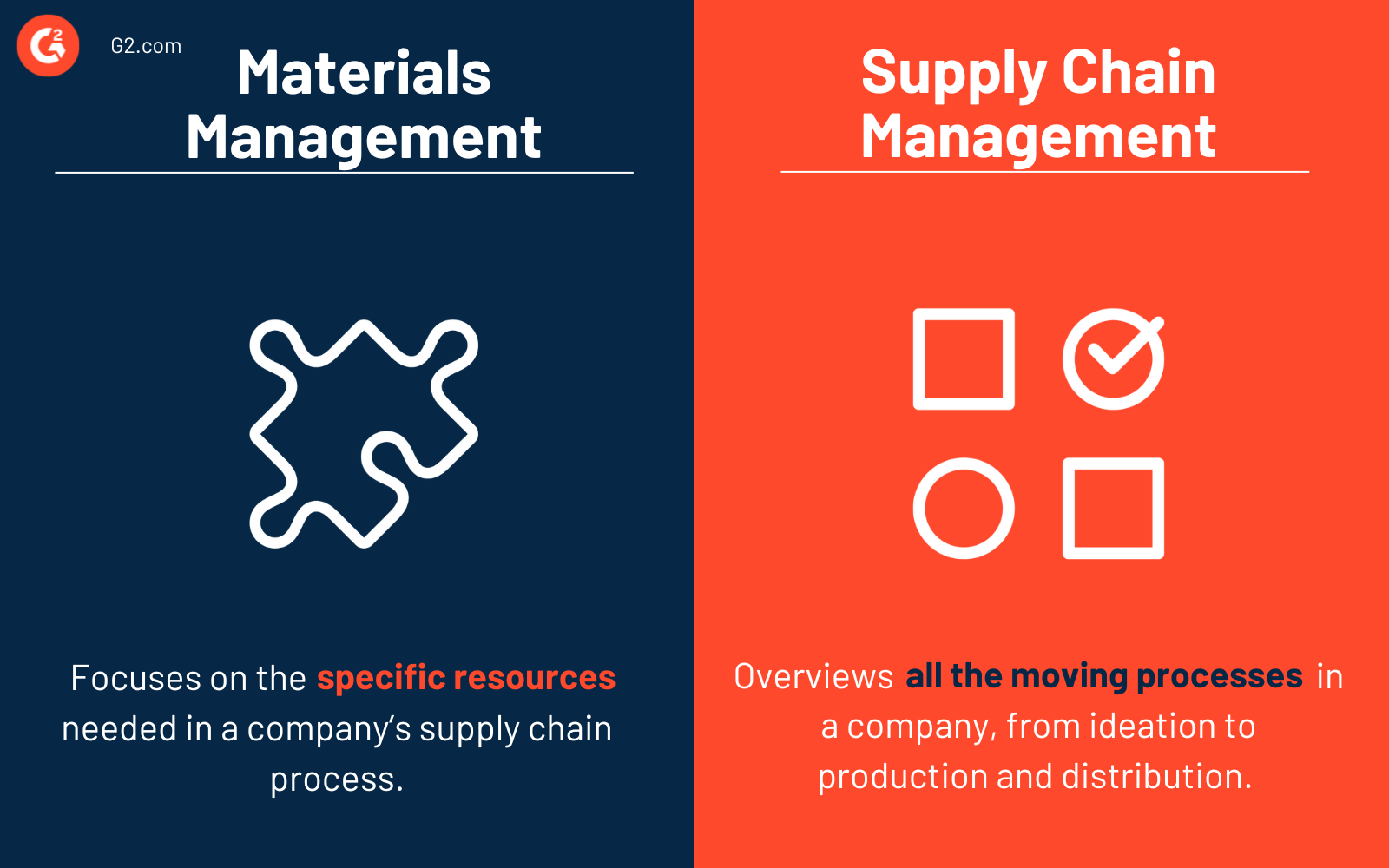

Although materials management is considered a subsection of supply chain management, the two are commonly confused. While both are necessary for an organization’s success, they differ in their applications and goals.

While materials management focuses more on the specific resources needed in a company’s supply chain process, supply chain management overviews all the moving processes in a company, from ideation to production and distribution.

Managing the supply chain is universal in its objectives. Unlike materials management, supply chain management is less involved in the specificity of the actual materials and more in how these materials help achieve the big business goals.

Supply chain management oversees a product’s entire workflow and how communication with any external suppliers and stakeholders is maintained. This includes budget preparation, record keeping, transportation, work-in-progress inventory, and delivery.

Materials management works in supply chain management by emphasizing the beginning of a good’s or service’s production. Supply chain management essentially creates the groundwork for materials management and takes control of distribution after everything is completed.

Alexandra Vazquez

Alexandra Vazquez is a former Senior Content Marketing Specialist at G2. She received her Business Administration degree from Florida International University and is a published playwright. Alexandra's expertise lies in copywriting for the G2 Tea newsletter, interviewing experts in the Industry Insights blog and video series, and leading our internal thought leadership blog series, G2 Voices. In her spare time, she enjoys collecting board games, playing karaoke, and watching trashy reality TV.