Professional services employees can work from home during these difficult times, but workers in industries like manufacturing and retail don't have this privilege.

Anyone working in warehouses, retail stores, construction, or production facilities needs to work in person due to the nature of the work. This exposes them to the coronavirus, on top of risks specific to their occupation, such as excessive noise, elevated or low temperatures, heavy lifting, or exposure to toxic fumes. Furthermore, work accidents may also cause environmental problems such as the spillage of hazardous chemicals and the release of toxic gases into the atmosphere.

Why does environmental health and safety (EHS) matter

To protect their employees and the environment, companies in the industries mentioned above adopted environmental health and safety (EHS) rules, guidelines, and software.

EHS rules are based on regulations defined and enforced by local, national, and international lawmakers. Any violations may entail fines and even suspension of business permits.

On the other hand, EHS guidelines are best practices or standards created by industry organizations such as International Organization for Standardization (ISO). Companies don't have to comply with EHS guidelines but they usually choose to, in order to gain the trust of their customers, employees, and other stakeholders.

Customers and consumers expect businesses to be environmentally friendly and guarantee employee health and safety. This is becoming an important consideration that may make consumers change their providers of products and services. As illustrated below, research by Accenture shows that 66% of people choose brands based on how they treat employees or how they source materials.

Source: Accenture

Finally, there is a more pragmatic reason why companies want to avoid accidents: cost.

Any disruption to operations can be costly for manufacturers or supply chain companies. Businesses can lose customers because of late deliveries caused by accidents. Companies may also lose money if their production costs are too high. For example, cleaning a polluted site can be very expensive, which has a negative impact on the profitability of the company, not to mention that compensation and fines can be hefty.

Principles of environmental health and safety

Protecting employees and the environment may seem straightforward, but it can be very complicated. New technologies and business models can help with, but also hinder, EHS initiatives. A great example is ride sharing, which was supposed to help reduce emissions by providing an alternative to driving personal vehicles. It turns out that it causes more traffic than it prevents; furthermore, ride sharing actually increased pollution levels in some densely populated US states such as Massachusetts.

Recent technology, including mobile devices, requires rare materials such as yttrium, lanthanum, or terbium. These elements are mostly found in developing countries, where their extraction and processing aren’t always regulated. It is not uncommon for local warlords to exploit native populations in illegal mining practices.

Unfortunately, most rare elements can be found in countries that don't have strict regulations to protect employees and the environment. Companies are trying to address these issues by adopting regulations such as the EU Conflict Minerals Regulation and by choosing not to do business with corrupt governments and abusive organizations.

To address environmental health and safety challenges, companies can take two approaches:

- Reactive is a method that involves focusing on identifying regulations and standards that the company has to comply with and then defining internal policies and rules that are enforced across the company.

- Proactive, which aims to identify risks and address them before they cause any damage, thus ensuring not only compliance with regulations, but also creating a safe and productive workplace.

Choosing one approach over the other depends on many factors, with the most important being:

- the company culture and how employees are treated (“assets” vs. talent)

- the industry and size of the company, as well as the complexity of its operations

- the technology available to tackle EHS challenges

Since technology is one of the main components of a successful EHS strategy, it is critical for companies to choose the best option for their specific needs.

What software should you use for EHS?

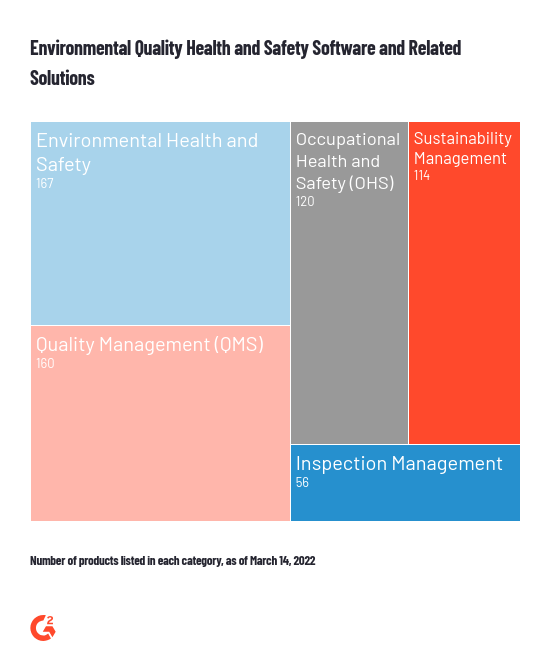

While EHS is a distinct software category, there are other solutions for occupational health and safety software (OHS), inspection management, or sustainability management which overlap in functionality with EHS.

EHS software provides functionality that companies use to define, implement, and monitor policies and procedures that aim to protect their employees and the environment.

EHS can be combined with quality management systems (QMS) to create software packages known as health, safety, environment, and quality (HSEQ) solutions. Finally, governance, risk, and compliance vendors sometimes include EHS functionality in their offering.

The huge number of local and international regulations, as well as the multiple occupational risks mentioned above, can make it difficult for software buyers to select, implement, and use EHS software.

My next article will focus on how various solutions help companies with EHS, describe the main differences between all the software solutions mentioned above, and how to choose the best option that fits particular business needs.

¿Quieres aprender más sobre Software de Salud y Seguridad Ambiental? Explora los productos de Salud y Seguridad Ambiental.

Gabriel Gheorghiu

Gabriel’s background includes more than 15 years of experience in all aspects of business software selection and implementation. His research work has involved detailed functional analyses of software vendors from various areas such as ERP, CRM, and HCM. Gheorghiu holds a Bachelor of Arts in business administration from the Academy of Economic Studies in Bucharest (Romania), and a master's degree in territorial project management from Université Paris XII Val de Marne (France).