The only thing between you and a streamlined production process is effective operations management.

Everyone wants to perfect the way they produce their company offerings. Managing staff, equipment, inventory, and technology can feel overwhelming, but operations management ties it all together neatly.

What is operations management?

Operations management is the process of organizing and optimizing the production and manufacturing of company products.

Operations management is all about creating a unique production strategy that satisfies company needs and fulfills manufacturing process expectations. Operations management takes supplied materials, hands them to employees, converts them into a product, and guarantees they meet predetermined requirements.

The start of successful operations management comes from preparing for customer needs. With demand planning, managers can meet future needs and achieve production goals using historical data.

All of these processes happen while an operations manager ensures that product quality never suffers, employees are satisfied with working conditions, and product waste is kept to a minimum. Creating an efficient production process doesn’t come easy, but taking steps toward it is.

The 4 Vs of operations management

Companies operate their production processes differently. And each has objectives and goals for staying relevant and successful in their target markets. The 4 Vs of operations management outline a company’s main product deliverables and key takeaways as it enters the market with a good or service.

1. Volume

Volume refers to the exact number of product units needed to fulfill customer demand. This dimension is especially detrimental for companies that prioritize mass production and extreme product output. For them, volume is a huge concern, but so is ensuring that despite supplying a large output, the quality of every unit is still up to market standards.

Volume is also the primary dimension that shows how well a company is performing in the market. After supplying products, a company can use volume information and sales numbers to make production changes.

To anticipate volume needs and prepare accordingly, some companies utilize demand planning tools to transform product data into future customer demand expectations.

2. Variety

Variety refers to the range of goods and services that a company creates and sells. This dimension outlines just how much diversity lives in a company’s product portfolio. Having a healthy variety of product offerings allows a company to avoid relying on one product to be successful and profitable.

For example, if one product is no longer serving its purpose in the product portfolio, there are others that can be prioritized and marketed to customers in its place. Companies that put all their eggs in one basket run the risk of being completely shut down in the case of a major product failure.

A wide variety of product offerings also opens the door to expanded target audiences and exposes the company to new customer demographics. While a specific customer might not be interested in one product, another product could be exactly what they are looking for.

3. Variation

Variation refers to what extent external factors affect customer demand for a product over time. For instance, the COVID-19 pandemic caused millions of people to flock to technology solutions to continue everyday tasks like working from home and connecting with friends and family.

If your company was selling licenses for a video chatting service, your product was probably met with some extreme levels of demand at that time. Your company has increased variation because you have a new external factor that heavily affects how many units you will need to produce and sell.

To determine what the variation is like for your company, consider your product and its audience. What could happen to your audience that would cause them to buy more or less of your product? If you sell hurricane impact windows, the weather would be a huge external factor affecting demand. Identify what other factors play into potential production changes and acknowledge them when making development decisions.

4. Visibility

Visibility refers to a company’s image in the marketplace and how customers perceive and experience their good or service. This dimension is essential for companies whose products “speak for themselves” in that their most effective advertising and marketing strategies lie in catching the attention of their target audience. This includes ensuring that all advertising is accurate and easy to comprehend. A huge way to lose visibility is to lose credibility.

Another huge aspect of visibility is ensuring a positive user experience. Is your product easy to understand, learn about, and access? Is the buying process for your product concrete and simple? If your product becomes a mission to acquire, fewer people will be willing to go through it all to get it. Additionally, do you consider visibility after the sale?

Modern companies have been implementing more ways for customers to gain visibility into their product even after it has been purchased, either through an internal tracking feature or simply by offering up-to-date delivery information. Considering the customer at every stage and opening up communication and visibility creates trust, promotes good reviews, and encourages repeat customers.

Now is the time to get SaaS-y news and entertainment with our 5-minute newsletter, G2 Tea, featuring inspiring leaders, hot takes, and bold predictions. Subscribe today!

Möchten Sie mehr über Bedarfsplanung Software erfahren? Erkunden Sie Nachfrageplanung Produkte.

Systems of operations management

Companies utilize four major operations management systems to optimize the way they organize their production process and respond to market changes.

The systems of operations management:

- Business process redesign (BPR)

- Reconfigurable manufacturing systems

- Six Sigma

- Lean manufacturing

Business process redesign (BPR)

The business process redesign (BPR) method consists of completely uprooting main processes to transform a business from the ground up. A company may want to try BPR if marketplace changes and needs are no longer aligning with the objectives and output of company production.

BPR is considered a relatively tedious process as it consists of identifying old methods that aren’t effective anymore, removing them, and swiftly replacing them with new developments as soon as possible.

Although you’re heavily restructuring company processes, business process reengineering and redesign has many benefits for quickly improving production. When changes are made rapidly and dramatically, less business time is used for maintenance and it lowers the chance of losing customers due to downtime. Implementing BPR unsuccessfully can be remarkably risky, so extensive planning is required.

Reconfigurable manufacturing systems

A reconfigurable manufacturing system was designed to be optimized and replaced in response to significant market changes. The reconfigurable elements can be anything from the entire manufacturing structure to more specific hardware and software components.

Reconfiguring manufacturing systems includes six main characteristics that work together to ensure that all elements of the operations method can be easily manipulated when necessary.

- Scalability: The ability to quickly modify by adding or removing materials and production capacity components.

- Customization: The flexibility to customize different production system elements.

- Convertibility: The ability to reconstruct current processes to adapt to new needs.

- Integrability: Combining different production elements using hardware or software.

- Diagnosability: The ability to control product quality assurance and identify the causes of production issues.

- Modularity: The categorization of product functionalities into well-rounded production units that can be easily molded to meet changing requirements.

These six characteristics allow a company to increase the speed in how they respond to market developments. Having these in place can even allow space for production failures like machine malfunctions or employee issues because of its emphasis on quick thinking and backup processes.

Six Sigma

Six Sigma is a quality improvement operations management system focused on identifying product deficiencies and addressing them. This method relies heavily on employee participation and detailed company data.

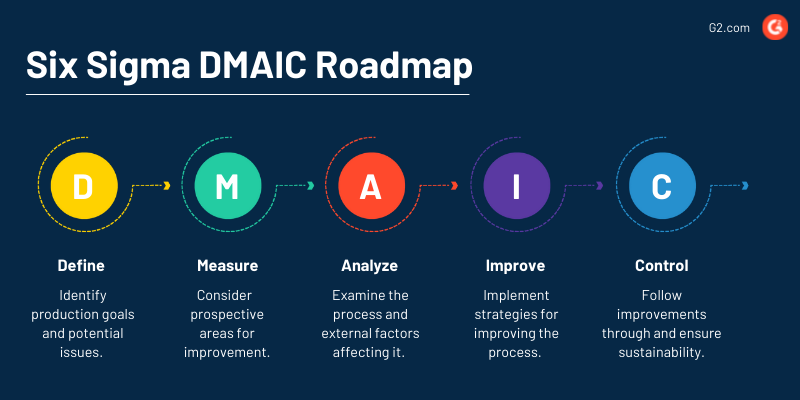

The Six Sigma system is structured using the DMAIC roadmap.

- Define: Recognize objectives for production and overall operations.

- Measure: Collect product data to uncover potential growth opportunities.

- Analyze: Conduct an in-depth analysis of product issues and pinpoint possible causes.

- Improve: Collect data from analysis to begin creating a plan of action for remediating issues. Implement those solutions.

- Control: Keep a close eye on those newly implemented solutions to ensure a positive result.

Lean manufacturing

Lean manufacturing focuses on decreasing production time. In this method, companies prioritize only ordering and receiving production materials as they are needed. The benefits include increased productivity and reduced inventory costs.

Lean manufacturing also helps companies to avoid the possibility of inventory shortages or surplus, as all supplies ordered are expected to be used immediately.

The disadvantages of lean manufacturing come from a very minimal room for error. This method requires extensive and accurate demand planning to predict the necessary amount of materials needed. If market demand fluctuates dramatically in any given direction, a company using lean manufacturing may not be equipped to meet orders.

The 10 decisions of operations management

A company’s operations management comes with many important and strategic decisions that must be made to keep everything running smoothly. There are 10 major decisions that an operations manager and team need to keep in mind as they optimize production procedures.

The 10 decisions of operations management:

- Goods and services

- Quality management

- Process and capacity design

- Location

- Layout design and strategy

- Human resources and job design

- Supply chain management

- Inventory

- Scheduling

- Maintenance

1. Goods and services

This decision revolves around a company’s product portfolio and what they provide to their customer base. This includes all aspects of creating the product, like the cost of production and resource allocation. It also relies heavily on extensive market research and target audience analysis and is a choice that transcends just operations management. All departments and teams should be involved in the decision-making for the final spread of goods and services.

At this step, some companies utilize product portfolio management to optimize their company offerings to meet market needs and objectives using product development strategies.

2. Quality management

Quality management involves decisions regarding the status of the products being sold. The customer determines the quality of the product, so decisions made here revolve around customer needs and wants.

Managing quality also relies heavily on ensuring every item manufactured and distributed is in good condition to be sold. Conducting quality control checks is essential in the operations management and production process.

3. Process and capacity design

Process and capacity design revolve around the strategies used in the production phase of product development. This includes production materials, technology, automation, and anything else that allows the process to continue smoothly. At this step, companies should prioritize creating a clear, well-researched production map.

The process design map outlines every step of the process, what’s needed at each stage, and what the output should be as production moves along. This decision can also include choices regarding what elements of production could be outsourced.

4. Location

Location is a crucial decision when determining what the most efficient method of movement in production is. This includes the actual location of the business and production spaces and the way things move within production, step by step.

Location decision-making entails finding a space ample enough for production, manufacturing, and distributing. Company location must include enough space for each of these processes to operate easily, with extra room for inventory and marketing efforts.

5. Layout design and strategy

Layout design and strategy are the decisions being made to optimize all physical resources. This includes determining the most effective way to organize desks, machinery, inventory, and guarantee safe working conditions for employees. The layout of operations is essential in assuring that the workflow is as streamlined as possible.

6. Human resources and job design

Human resources and job design focus on ensuring that all company employees are happy and equipped to perform. This includes conducting regular employee evaluations and satisfaction surveys. Employee evaluations should be used not only for judging performance, but also for identifying strengths and weaknesses.

Uncovering major strengths and weaknesses can open opportunities for utilizing employees with particular specializations or employees who no longer enjoy their current conditions in other production areas where they can strut with confidence. Satisfaction surveys are also essential in assuring that all team members are content with their working situations – and if not – those concerns can be addressed efficiently.

Operations managers should also ensure that there are no opportunities for bottlenecks. A bottleneck is when employees are met with a workload so overwhelming that production starts to delay in order to catch up. Effective human resources and job design would prevent this by assuring that all tasks are fair and work is allocated appropriately.

7. Supply chain management

Supply chain management in regards to operations functions by securing constant and effective communication with stakeholders and suppliers. It also includes decisions regarding sourcing suppliers, who suppliers should be, and how much should be outsourced from them.

8. Inventory

The main goal of inventory is to create an organized environment for the production process. Inventory management can add to the organization of sales orders, supply chain management processes, deliveries, purchases, and more.

Creating an efficient inventory process means ensuring that all necessary resources are available and production materials are accessible with the proper inventory management method.

There are four different types of inventory management systems: perpetual, periodic, barcode, and radiofrequency identification (RFID). Identifying your inventory needs and overall company objectives when it comes to inventory in production is essential when choosing a method.

Are you a small business that prefers taking stock manually with little technology interference? Try the perpetual or periodic system. If you would like to try an automation tool for virtually counting inventory, try the barcode or RFID system.

9. Scheduling

The scheduling decisions center around how timing will work for the entire production process and those involved. This includes how many products can be made at a given time, how many people are needed to meet quotas, and how the speed of production can be optimized.

Getting these metrics relies heavily on those who are consistently hands-on in the production process. Those key players can offer an invaluable perspective on exactly how production works from minute to minute and what scheduling changes are needed to streamline the process as a whole. Scheduling can also include whether automation can play a role in facilitating the process.

10. Maintenance

Maintenance is necessary to ensure that things continue to go to plan far after production has begun. This includes securing resources as they are needed, conducting regular machinery and workplace inspections, and maintaining accurate counts of raw materials and final products as they are used or sold.

Maintenance is a constant process, so some companies have implemented entire maintenance teams whose daily goals are to guarantee that everything needed for production is accessible and ready to use at all times.

What does an operations manager do?

An operations manager is responsible for overseeing the daily activities involved in company production. Operations management is ongoing and starts from the first day of product ideation to the last day of production and distribution.

Operations managers are tasked with forming product strategies, creating plans for obtaining resources, leading product design and production, balancing and allocating budgets, and supporting and advocating for production teams.

While ensuring that everything is running smoothly internally, their obligations are also valid externally. An operations manager is a prominent leader in guaranteeing that new products get into the hands of customers. This includes making sure that the amount of items demanded is made efficiently with quality control at the forefront.

An operations manager makes decisions in three major areas: assets, costs, and human resources. For asset management, an operations manager oversees how business operations are conducted physically in production facilities, how equipment is chosen and maintained, and how stock is used and replenished.

Operations managers control costs in producing goods and services, budgets to purchase necessary materials, and expenses incurred in distributing the products to customers. Last but not least, operations managers play a huge role in human resource management as their role ties into employees, stakeholders, retailers, and suppliers and their happiness and safety at the company.

Operations management vs. supply chain management

Operations management and supply chain management work very closely in problem-solving and making a company’s production process run smoothly and efficiently.

The most significant difference between operations management and supply chain management is their involvement with the internal and external parts of producing and distributing.

Operations management takes a lot of focus on the internal elements of production. It is mainly concerned with how things are running within the company walls and how those factors will affect product development, including employee satisfaction and working conditions.

Supply chain management plays a more prominent role in what happens with a product as it is moved through production, especially when it leaves company property. While an operations manager oversees employees and internal inventory, a supply chain manager focuses on gathering materials before producing and distributing finished products.

Another difference between operations and supply chain management is who they interact with and are responsible for. An operations manager is overseeing daily operations and ensuring well-being in the workplace. A supply chain manager is spending more time talking to external stakeholders, suppliers, and customers.

Despite these differences, operations and supply chain need each other to create a successful production process. Supply chain management gives operations management the tools to create a product and the means for getting it into customer hands. The two work so closely that some companies choose to overlap them to save money and increase communication performance.

Operations management challenges

There are several challenges that operations managers face as they plan and maneuver through the streamlining of the production process. These challenges include internal and external factors that affect both daily company operations and decisions for the future.

1. Adapting to globalization

Globalization is the process of goods and services being spread internationally. A company is experiencing globalization when they are able to operate and sell products worldwide. With the perks that come from globalizing, operation managers also experience increasing competition. As a company’s target market grows globally, so do opportunities for international opponents.

Another challenge in globalization is appealing to a myriad of new audience members. Every country, state, and city has needs that are unique to them and may look completely different than the needs of those nearby. Operation managers take on the brunt of these challenges when determining what has to change regarding product planning, inventory management, and marketing.

2. Balancing sustainability

Sustainability is all about guaranteeing that a product or service can last in the marketplace while the company continues operating the way they are. This can also be on a large scale, with some companies trying to ensure that their sustainability practices don’t negatively affect the world in the future.

There are three pillars of sustainability that categorize exactly what ways company operations affect the marketplace and the world.

- Economic sustainability refers to how secure a company feels in its place in the market. The main component of economic sustainability is assuring that a company can achieve profitability. This includes creating risk management plans, adhering to government compliance policies, and ensuring stakeholders and investors are satisfied with company operations.

- Environmental sustainability focuses on a company’s carbon footprint and how its daily operations affect the environment. Companies that prioritize environmental sustainability will reduce unnecessary waste, recycle production materials, and use environmentally conscious machinery. This pillar can create costs for companies that may restructure production and/or move locations altogether to meet these environmental standards.

- Social sustainability focuses on how the company is perceived and approved by the people around them. This includes employees, stakeholders, community members, and potential customers. When it comes to employees and internal individuals, a company prioritizing social sustainability will concentrate on offering good benefits and time off. On a global scale, audiences are expecting companies to operate more humanely. A socially sustainable company would want to ensure that they are offering safe working conditions and ethical pay.

Sustainability is considered a challenge because it forces companies to prioritize long-term planning over short-term planning. While some companies put short-term profits first, a sustainable company will plan for long-term growth and development to create a more long-lasting reputation and use that reputation to sell an ethical good or service.

3. Creating effective communication

As simple as it seems, effective communication is not a given for many companies.

Operations management departments have a considerable amount of responsibility to bridge communication gaps between internal and external stakeholders. This includes ensuring that everyone from the part-time intern to the chief operating office (COO) are on the same page regarding company goals and objectives. Having any miscommunications, minor or major, can create many issues within the organization.

Miscommunications cost time and money to remediate and create synergy within the company again. Creating an operations management team that prioritizes good communication creates a working environment of trust and high productivity.

4. Achieving ethical conduct

As touched upon in sustainability, ethicality is a huge priority, especially as customers continue to demand that companies reevaluate their operations and produce more ethically overall. This is challenging when you consider how many working pieces there are in a business structure. Ethical conduct publicly and privately is essential for companies who hope to create long-term success.

If you’re wondering just how much ethical practices can affect a company’s operations, check out the examples below.

Example of unethical conduct

One of the most infamous examples of a company that endured the repercussions of conducting unethical business practices is Enron. The energy company was created in 1985 and experienced major stock market success after 1995.

In 2001, Enron was exposed for committing extremely unethical accounting practices. After skeptical eyes wondered how Enron was amounting to such success, research showed that some high-profile executives were adjusting numbers and manipulating documents to collect more money from investors. This unethical scandal resulted in Enron declaring bankruptcy and the CEO being sentenced to 24 years in prison.

Example of ethical conduct

A company that has reaped the benefits of ethical business systems is General Motors. General Motors was recently named one of the 2020 World’s Most Ethical Companies, a ranking that assesses companies’ reputations, culture, compliance, citizenship, and more. They accredit this honor as a result of their objective to create a world with zero carbon emissions in the automotive industry.

Operations management benefits

Despite all the challenges, operations management continues to offer many invaluable benefits. These benefits outline what an effective operations management plan can do to improve various aspects of your company processes.

- Expertly allocating resources helps to reduce waste, and save money by only budgeting for materials that will be used.

- Gain competitive leverage in the target market by streamlining operations and getting products distributed faster.

- Keeping a close eye on ethical conduct allows companies to achieve compliance and avoid potential legal issues.

- Increase quality control with an operations management plan that designates ample time for assuring that only the best products leave company grounds.

- Create a safe working environment to retain employees, keep them happy, and give them a secure space for voicing popular opinions.

- Improve customer satisfaction by offering quality products quickly.

Operations management best practices

With everything in mind, there are a few ways that a company can conduct operations management more efficiently. These best practices offer areas of focus that can improve daily operations and overall company administration and success.

Stay up-to-date

One of the best ways to know whether a product will be welcomed into the market is to become an expert in what the market wants. There are constantly new and moving innovations in every aspect of a business, especially technology.

Keeping up-to-date on changes in the market can sometimes be costly in both time and money, but the competitive advantages far outweigh the disadvantages. Training is periodically necessary for ensuring all employees understand any technology implemented and companies should prioritize updating that technology to the latest innovations as often as possible.

Keep communication flowing

There is no such thing as too much communication. Keeping open lines of communication between every part of an organization, especially at all stages of production, creates fewer opportunities for mistakes.

Miscommunications cost valuable time and money to clear up and reverse. Open communication builds productivity and trust that everyone in the organization is on the same page and understood.

Collect data

Historical information creates future opportunities. Gathering as much company data as possible helps identify any potential production issues and find necessary improvements. Collecting that data electronically also allows for better communication as all information is updated and available at all times.

Forecast demand

To manage operations effectively, companies need to outline precisely what production expectations are. This includes conducting accurate analyses and forecasting demand.

To start planning for future demand, identify outside factors affecting production, analyze previously collected historical data, obtain multiple internal and external perspectives, distinguish company key performance indicators, and closely monitor market changes.

Creating a comprehensive understanding of customer satisfaction and upcoming needs allows you to prepare for unexpected fluctuations and jump on potential growth opportunities.

Manage inventory

Successfully managing inventory allows companies to know what resources are available and refresh them as they are needed without overspending on unused items.

There are several inventory techniques you can use to replenish inventory and organize stock effectively:

- Just-in-time (JIT): This method focuses on only purchasing items as they are needed for production. JIT relies on companies staying up-to-date on orders as they come in and gathering the necessary materials in time for the products to be created.

- Economic order quantity (EOQ): The EOQ model utilizes a formula to determine inventory needs based on historical customer demand. After multiplying demand units and the setup costs by two, dividing by the holding costs, and taking the square root of the final number, you will be left with what should be your ideal inventory necessities.

- First-in, first-out (FIFO): This method prioritizes using the oldest items as soon as possible. This method is especially beneficial for companies that offer perishable products.

- Last-in, first-out (LIFO): This method prioritizes using the most recently acquired materials in production first. This method would mainly be used by companies that offer nonperishable products. A company might opt for LIFO to keep inventory that is already organized and accounted for in order.

- ABC analysis: The ABC method categorizes inventory into three tiers from A to C in order of importance. Using this method, companies can not only identify what items need to be replenished but how quickly and how often.

Ensure employee satisfaction

As mentioned earlier, employee satisfaction is essential for an effective day-to-day operations process. When employees are happy, company processes run smoothly and more productively. Happy employees are also more likely to offer time towards improving the company as a whole.

When employees enjoy where they work, they will be able to identify rooms for improvement and feel comfortable sharing those insights with management. Creating a safe and healthy work environment opens the floor for questions and concerns that may turn into ways to enhance how the company operates altogether.

Employee satisfaction also includes providing practical training. Training helps employees feel confident in their individual responsibilities and clears up any confusion regarding their role in the organization.

Automate the process

If managing each step manually seems a bit tedious, consider implementing automation into your daily operations. Using the right piece of technology for automating operations management saves time, money, and resources in the production process.

The best software for your business is one that creates a constant flow of communication between departments, blocks potential issues from occurring, streamlines tedious processes, leaves little room for misunderstandings, and helps to identify potential opportunities for growth before you even knew they were there.

If you start implementing significant software-as-a-service (SaaS) applications within the process, consider using SaaS operations management tools to organize all technology solutions, control user and team access, and manage security policies within the platforms.

Everything goes to plan when there is a plan

Operations management is all about creating a thriving working environment and efficient production plan. There are different systems to choose from, but what is most important is that you choose the one that fits your company’s needs.

Operations management is also met with many challenges. From adapting to globalization to ensuring sustainability, there are several things to keep in mind when developing your operations management plan.

How will you organize inventory? What can you do to ensure employees are happy? Will you implement operations software? There are so many decisions to make before your operations management process meets its full potential. But managing operations effectively will be worth the time and effort.

“In the end, all business operations can be reduced to three words: people, product, and profits.” - Lee Iacocca

Ready to start streamlining your operations management strategies? Learn more about how overall process optimization can improve daily business operations.

Alexandra Vazquez

Alexandra Vazquez is a Senior Content Marketing Specialist at G2. She received her Business Administration degree from Florida International University and is a published playwright. Alexandra's expertise lies in writing for the Supply Chain and Commerce personas, with articles focusing on topics such as demand planning, inventory management, consumer behavior, and business forecasting. In her spare time, she enjoys collecting board games, playing karaoke, and watching trashy reality TV.