Something’s lurking in the dark corner of your warehouse. It’s the deadstock.

Understock and excess inventory are known to haunt the dreams of supply chain professionals. Juggling the delicate balance of not enough, enough, and more than enough spells all the difference between success and struggle in the supply chain realm.

To avoid this, you should have a plan for inventory optimization. At its core, inventory optimization is a strategic management process that ensures the right products are available in the right quantities and at the right time.

Supply chain professionals often turn to tools like inventory control software to harmonize inventory costs with customer needs. They utilize advanced data analytics, real-time insights, and forecasting techniques to predict future demand, determine optimal inventory levels, and push data-driven decisions.

What is inventory optimization?

Inventory optimization (IO) is the strategic management of inventory. Practicing IO balances supply and demand, reduces inventory holding costs, and increases customer satisfaction. The process involves demand forecasting, advanced inventory management techniques, and data-driven insights to ensure operational efficiency and greater profitability.

Optimizing inventory is all about finding the right mix of having enough products to meet customer demand and avoiding the headache of excess inventory. It is also about managing a healthy cash flow, where you’re selling enough products without keeping inventory that ties up your working capital.

If you want to discover how to stock your shelves with the right amount of product, read on.

Multi-echelon inventory optimization

Multi-echelon inventory optimization (MEIO) makes inventory levels precise across multiple stages or echelons in the supply chain. The process analyzes historical and market data to increase forecast accuracy and then determine how much inventory you keep at each echelon. Doing so minimizes stockout chances while reducing carrying costs and excess stock. The idea is to look at the bigger picture instead of managing each stage separately.

MEIO maximizes your supply chain performance so you’re always prepared to meet customer demands while keeping your investing cost in check. Please note that you should have good communication and collaboration between different parts of your supply chain team to make multi-echelon inventory optimization truly successful.

Want to learn more about Inventory Control Software? Explore Inventory Control products.

Single-echelon inventory optimization

Unlike MEIO, single-echelon inventory optimization (SEIO), or just plain IO, focuses explicitly on improving inventory management for single units or individual echelons, independent of other echelons and locations. The goal of this strategy is to consider the demand for each point, like a single retail store or a warehouse, rather than trying to fix the entire supply chain network as a whole.

With the help of accurate demand forecasts and required safety stock, you can balance inventory for the considered location as you overcome challenges like lead time variability and demand volatility.

Whether you choose SEIO or MEIO depends on the nature of your business. Single-echelon inventory optimization is the right choice if you build customized products and have a relatively straightforward supply chain business network with few distribution nodes.

On the other hand, if you manage a large volume of products and multiple distribution channels, such as regional distribution centers and retail outlets, multi-echelon inventory optimization likely best suits your needs.

Importance of inventory optimization

Inventory turnover depends on social trends, economics, natural events, competition, and politics. Consumer behavior, which has tremendously changed over time, also profoundly impacts inventory turnover. Online shopping is at an all-time high, and customer expectations for delivery timelines are getting shorter by the day.

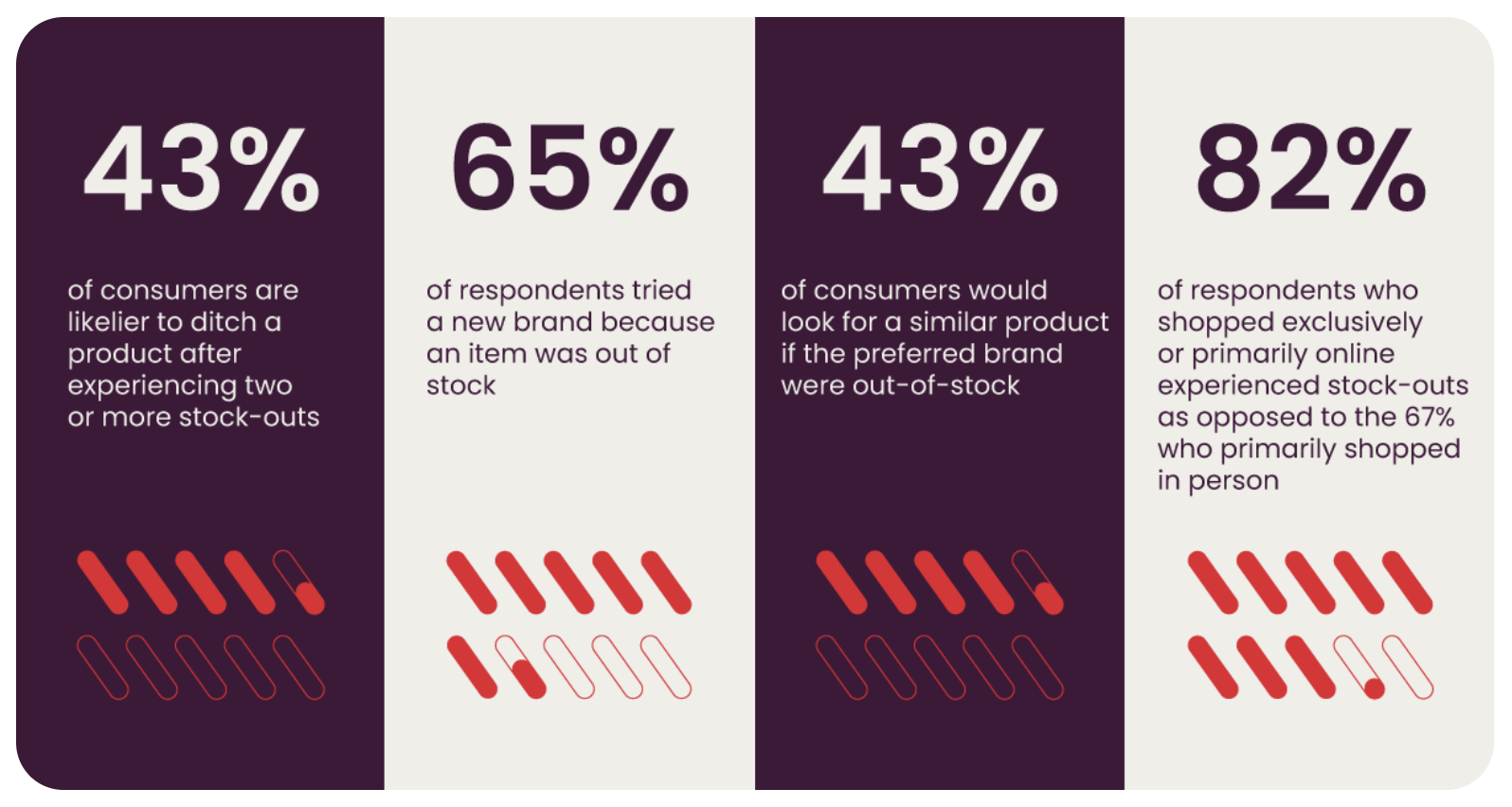

Even though many of these factors aren’t under our control, proper inventory optimization helps avoid the pitfalls of stockouts and excessive stockpiling. Stockouts lead to dissatisfied customers and a fall in brand image, while excess inventory increases carrying costs, disturbing your bottom line.

This strategic approach promises the availability of desired products and customers' happiness, all while liberating valuable capital and amplifying profitability. Inventory optimization also allows you to respond quickly to market changes so you stay agile in the dynamic business environment.

In short, IO opens doors for new opportunities, prevents lost sales, reduces damage in unfavorable situations, and minimizes the chances of disappointing consumers.

Source: Netstock

Inventory optimization in retail

Retail is a highly competitive industry that sees the most consumer-related changes, making its inventory optimization process even more important than in other industries.

In the fast-paced retail landscape where consumers have high expectations for product availability, stockouts severely weaken reputation and customer loyalty. Excess inventory is equally detrimental because it’s a financial burden and a roadblock in business investment. The risk of wasting products that have become obsolete or unsellable also rises.

By mastering inventory optimization, retailers can precisely adjust inventory levels and better manage demand and supply. Inventory optimization is also used to assess high-performing products so they can swiftly be replenished.

Related: Retailers currently possess unsold merchandise amounting to $740 billion in the US alone.

Key elements of inventory optimization

You should keep a few considerations or critical elements of inventory optimization in mind to confirm that you always have the right amount of product on hand. Demand forecasting, inventory levels, storage capacity, and replenishment are important aspects that maintain a balance in the supply chain. Further, taking note of supplier lead times, schedules, and seasonal trends always helps.

Demand forecasting

Accurate demand forecasting is the foundation of inventory optimization. It relies heavily on historical sales data, real-time inventory, market trends, and consumer behavior. Making a demand prediction using these points helps businesses line up their inventory levels with customer needs, preventing overstocking and understocking.

Using the right tools and technology facilitates better projection of consumer demand, empowering you to identify slow-moving items, lessen inventory holding costs, strengthen the supply chain, and deliver an enhanced customer experience.

Inventory levels

At any given moment, the number of products in your stock represents inventory levels. Maintaining excess inventory ties up capital and incurs storage expenses and inadequate inventory leaves you with stockouts and disgruntled customers (to reiterate for the third time).

Correct inventory levels are crucial for grabbing sales opportunities and creating happy customers. You achieve this feat by carefully analyzing customer needs, seasonal variations, and understanding product lifecycles.

Inventory storage

Having the right storage is just as important for inventory optimization. Inventory storage can be any space, like warehouses, third-party fulfillment centers, distribution centers (DCs), or self-storage. Your desired storage will depend on your sales volume, product attributes, and shipping locations.

Store your inventory in a space that lets you quickly fulfill consumer demand. Having fulfillment centers or DCs for places with high consumer demand allows you to deliver the products faster and lowers operational and handling costs.

Replenishment

Replenishment is the process of receiving more products from the manufacturer to build stock and return to optimal inventory levels. Implementing effective replenishment strategies prepares you for unexpected fluctuations and maintains the right inventory balance.

Replenishment involves answering when and how much to reorder based on factors like lead times, supplier performance, and demand variability. You also have to consider each stock keeping unit’s (SKU) reorder point, current inventory levels, safety stock levels, and the best order quantity.

10 inventory optimization techniques

In this section, we’ll review a few inventory optimization techniques that will make you go from “just Michael” to “inventory-wizard Michael.” At the end of this section, you’ll know how to avoid the frantic rush to restock, the dreaded stockouts, and the dismay of missing a sales opportunity.

1. Demand planning

Demand planning involves understanding which products customers are likely to purchase and how much inventory you’ll need to cover those sales. Besides looking at historical data and trends, recruit your sales force and on-the-ground personnel to get a clearer view.

Advanced technologies like machine learning also facilitate better decision-making by quickly and accurately assessing previous sales data, current inventory levels, and potential future sales volume.

With the right plan and forecast, you can make informed choices about resources, storage space, flash sales, outsourced order fulfillment, and competitive price points.

2. Safety stock inventory

Uncertainties are a certainty in the supply chain world. Safety stock or excess stock serves as a protective buffer against disruptions. It makes sure you have enough items to cover unexpected demand spikes or delays due to supply chain confusion. It also protects you against inaccurate forecasts, financial constraints, and reordering failure.

Calculating safety stock inventory might require some mathematics, depending on the speed of inventory movement, demand and sales volume, and supplier lead times.

Basic formula for safety stock calculation:

Safety stock = number of products sold per day multiplied by the number of days safety stock is required

Example: You are selling 500 items daily and want ten days of safety stock due to an unexpected rise in demand. With this simple formula, you figure out that you need 5,000 (500 x 10) units to avoid a quick stockout. Variables such as demand and lead time are not considered; it’s just a guesstimate.

3. Reorder point (ROP)

The reorder point is the tipping point between reordering inventory and experiencing stockouts. Calculating it accurately is crucial. The basic formula below is a starting point, but businesses should consider more sophisticated formulas.

ROP = demand during lead time + safety stock

For example, if you’re selling 10 units of your product per day through a lead time of 50 days, demand during the lead time is equal to 500 units ( 50 x 10 ). Let’s say you have 1,000 units of safety stock. According to this example, you should order more products when you have 1,500 units (500+1,000).

The formula is fine for a simple calculation like this, but automating this process using software will prove to be a wise choice for more accurate inventory optimization.

4. Buyer behavior and trends

Keeping a finger on the pulse of consumer behavior and market trends is vital in a dynamic marketplace. Behavioral and data analytics allow sellers to peek into consumer minds and predict which products will likely sell out and which items should be retired.

This requires a comprehensive study of consumer preferences, purchase patterns, evolving demands, and in-depth market research. Doing so, you’ll grow to understand the products that resonate most with the target audience so you can proactively align your inventory levels. It also gives you insights into which items can be unloaded through promotions or campaigns to generate quick cash.

5. SKU rationalization

SKU rationalization is a decluttering technique that evaluates and sorts products to improve operational efficiency, improve inventory turnover, reduce holding costs, and increase profitability.

The approach includes assessing the performance of each SKU in the product portfolio based on metrics such as sales volume, contribution to overall revenue, and demand patterns. Your goal is to identify and retain high-performing SKUs while reducing or eliminating low-performing products.

However, SKU rationalization is an ongoing process. You must reassess and manage your product portfolio and optimize the inventory mix based on market trends and customer preferences.

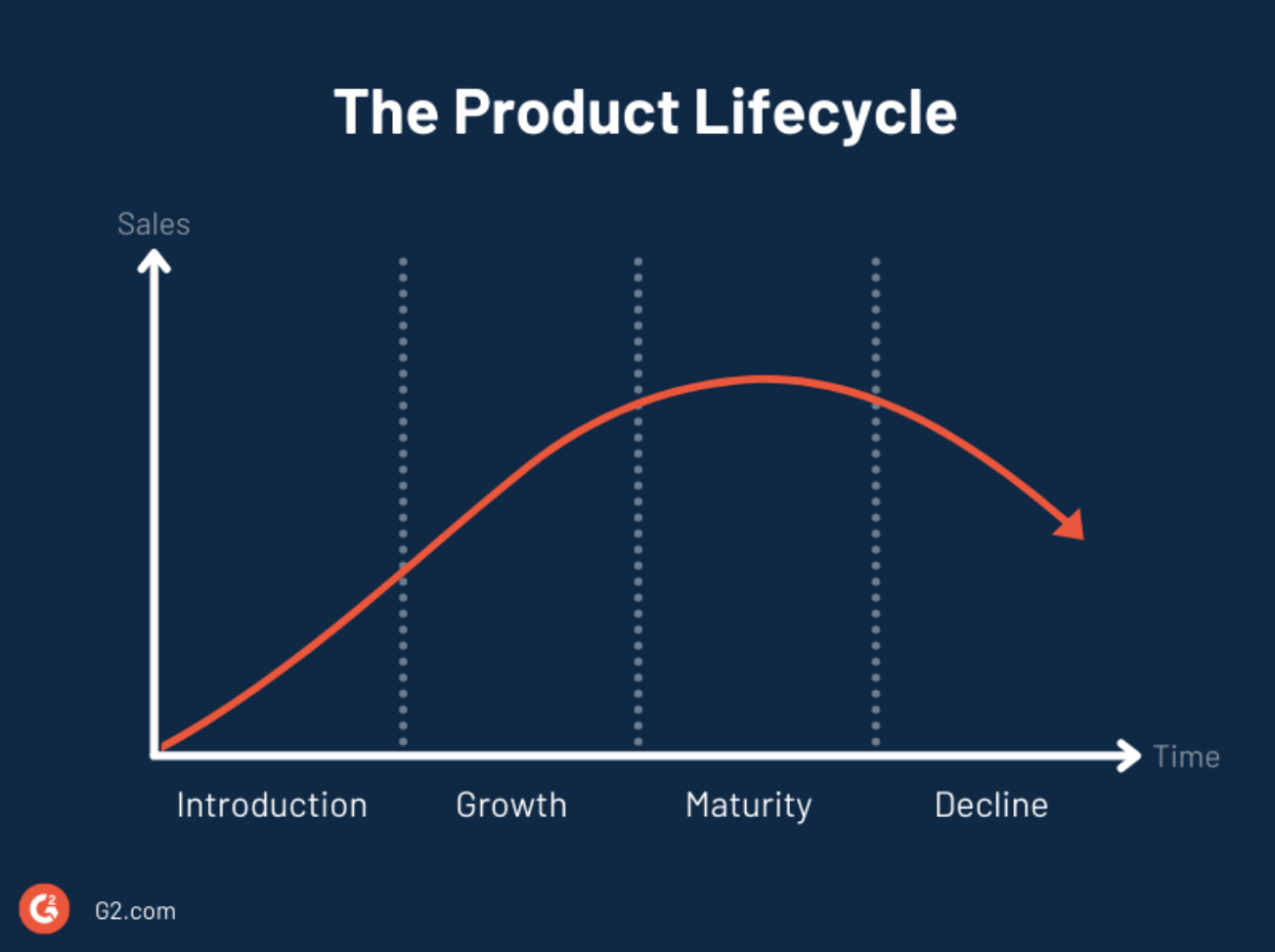

6. Product lifecycle

Understanding the product lifecycle is essential for strategic decision-making. A product goes through four phases in its lifetime: introduction, growth, maturity, and decline.

During the initial introduction phase of limited demand, it’s important to gauge customer response to predict future sales. As a product enters the growth phase, demand surges, so you should scale up your inventory. Inventory optimization at this point leads to significant revenue growth and competitive advantage.

As the maturity phase takes over, demand stabilizes, and managing optimal inventory levels becomes challenging, bringing a high risk of overstocking and stockouts. Non-evergreen products drop in demand at the decline stage before eventually dying out. It’s best to decide how to phase out products and liquidate the remaining inventory at this stage.

By factoring in the product lifecycle, you can proactively adjust your inventory to align with changing market dynamics.

7. Inventory policy

Crafting a well-defined inventory policy sets the foundation for efficient management. It should outline guidelines for order quantities, lead times, safety stock levels, and inventory turnover targets, all while ensuring that decisions are consistent with business objectives. Facilitating better communication and coordination among different people involved in the supply chain is a must for this strategy.

An inventory policy also dictates how and when products should be reordered. E-commerce brands can follow either a continuous review or a periodic review policy. A continuous review policy means that products are ordered once the inventory reaches the reorder point, whereas replenishment is done within set periods, like 500 units every 60 days, with a periodic review policy.

8. ABC analysis

Not all inventory items contribute equally to a company’s success. ABC analysis categorizes items based on their importance. A-items are high-value, high-impact products. B-items are moderately important, and C-items have lower values and may require more relaxed management. This prioritization ensures that products are restocked effectively, focusing on stocking items that deliver the highest value to customers and businesses.

The steps break down a basic ABC analysis.

- For each item in the inventory, gather data about sales history, purchase price, and usage frequency.

- Assign a value to each item based on its importance.

- Categorize the items into groups A, B, and C, with A being the most important and valuable and C being the least important and valuable.

- Adjust inventory levels based on the above categorization. Pay the most attention to A-items and maintain stock levels for those products.

9. Just-in-time (JIT) inventory

This approach tries to minimize inventory carrying costs by receiving products exactly when they’re needed for production or sale. JIT requires a reliable supply chain and close collaboration with suppliers. Executing successfully lowers warehouse costs and eliminates waste, leading to leaner operations.

To implement just-in-time inventory:

- Assess your current inventory management and procurement processes

- Map out your production process to better understand the inventory needs

- Communicate closely with suppliers for a smooth material flow

- Continuously monitor and improve your operations

10. Inventory optimization software

Maintaining an Excel sheet is okay, but manual processes take too much time and create many mistakes. Inventory optimization solutions combine data analytics, artificial intelligence, and machine learning to analyze vast amounts of data and make fact-based inventory decisions. This kind of software can also simulate various scenarios to identify the best strategies for different situations.

Key features and functionalities of inventory optimization software typically include:

- Future demand forecasting using historical and current data and other relevant factors

- Reorder point calculation based on demand variability, lead times, and desired service levels

- Safety stock management employing advanced calculations for determining appropriate excess inventory

- Economic order quantity (EOQ) calculation for each item based on order costs and holding costs

- Real-time insights for inventory levels, sales data, and other metrics

- Integration capabilities with other business systems, such as enterprise resource planning (ERP)

How to deal with a stockout

In the unfortunate event of a stockout, you can always offer to send a back-in-stock email or sell products on backorder. This can relieve some frustration and keep customers engaged.

Benefits of inventory optimization

From growing cash flow to keeping customers happy and satisfied, inventory optimization (IO) is the unsung hero of supply chain operations. IO's benefits extend beyond limiting inventory surplus or scarcity.

Optimizing inventory offers small and large businesses benefits like scalability, cost savings, better customer and vendor relationships, and competitive advantage.

- One of the most significant benefits of IO is cost reduction. By managing the optimal amount of inventory, you minimize the revenue erosion associated with excess stock.

- By implementing inventory optimization techniques, customer orders are fulfilled promptly and efficiently. Improved customer service increases customer satisfaction and loyalty, driving repeat business and positive word-of-mouth referrals.

- Better supplier relationships result from working closely to adjust inventory levels. Building stronger relationships via effective communication and collaboration leads to better negotiation terms, preferential treatment, and increased reliability.

- Inventory optimization gives you a look into high-performing inventory, the products with a potential for significant financial turnover that generate the most revenue.

- Another common benefit is increased inventory turnover. With a higher inventory turnover rate, fast-moving products spend less time on the shelves, reducing the risk of obsolescence and ensuring proper working capital utilization.

- Inventory optimization keeps operations efficient as your business expands, freeing you to handle increased demand and seamlessly expand your market presence.

- Finally, it’s a no-brainer that you definitely have a competitive advantage with all these benefits.

Challenges of inventory optimization

Since external factors are involved in moving inventory, challenges with inventory forecasting and supply chain management are expected. However, a proactive approach, strategic planning, investment in technology, and continuous improvement can build a more resilient supply chain, but only if you know what to look out for.

- Unfortunate events such as a global pandemic, natural disasters, or geopolitical tensions cause supply chain disruptions that lead to inventory shortages. Building resilience and flexibility in the supply chain is crucial to handling these situations.

- Limited visibility hinders effective decision-making if you manage inventory levels across various locations. Identifying potential overstock or stockout on time is a real issue without real-time data.

- Dealing with seasonality and demand spikes poses a significant challenge. You must factor in these fluctuations and variables to have just the right inventory.

- You are adding to your challenge if you still stick to the error-prone outdated processes and tools like manual updation or spreadsheets. For effective inventory optimization and greater visibility into all supply chain nodes, you need advanced tools with features like automation, real-time insights, and analytics.

17%

of inventory issues are traced back to wrong product packaging and delivery, leading to lost customers.

Source: G2

Inventory optimization best practices

Every company is different, and so are its inventory optimization requirements, but here are some best practices that can elevate your experience.

- Appoint a dedicated inventory manager to guarantee focused attention on inventory-related tasks and effective implementation of optimization techniques.

- Encourage collaboration among sales, operations, and purchasing departments to foster better demand forecasting, inventory decision-making, and replenishment.

- Establish key performance indicators (KPIs) to measure inventory performance regularly. Track metrics such as stockout rates, inventory turnover, lead times, and inventory carrying costs to measure the effectiveness of your optimization efforts.

- Conduct frequent inventory audits to reconcile recorded data with the actual inventory. This ensures data accuracy and identifies any discrepancies.

- Listen to your customers. Regularly check for feedback from all your customers and make decisions based on them.

- We’ve said this before, but it warrants repetition: invest in inventory optimization solutions to automate tasks, get real-time visibility into inventory data, and generate data-driven insights for better decision-making.

Inventory optimization software

Inventory optimization tools help simplify processes, enhance decision-making, and maximize operational efficiency. The software uses data analytics, advanced algorithms, and sometimes artificial intelligence to better understand the supply chain and improve inventory accuracy.

Inventory control software is an optimization tool that offers a centralized system for monitoring stock levels, tracking inventory movement, and refining inventory operations.

The software often includes warehouse management and barcode features to form an all-in-one inventory management solution.

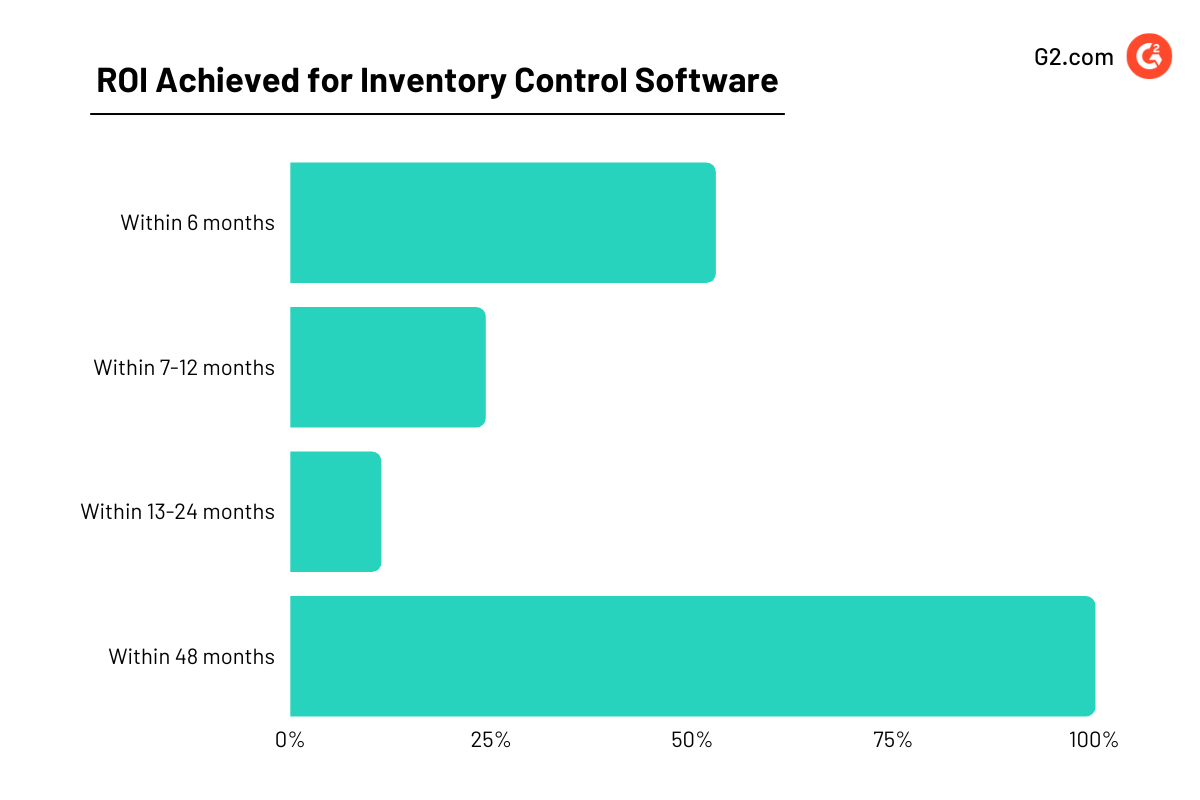

According to G2 review data, 52.8% of users achieved a return on investment (ROI) within 6 months of implementation. 24.19% of users gained ROI within 7 to 12 months, and another 11.21% saw a return on investment in 13 to 24 months.

Overall, almost all respondents reported gaining ROI within 48 months.

To qualify for inclusion in G2’s inventory control software category, a product must:

- Have inventory forecasting tools

- Provide a centralized inventory database

- Contain asset tracking technology like barcode or radio frequency identification (RFID)

* Below are the top 5 leading inventory control software from G2’s Fall 2024 Grid® Report. Some reviews may be edited for clarity.

1. QuickBooks Online

QuickBooks Online is cloud-based accounting software for tracking inventory finances. It offers helpful features like invoicing, income monitoring, and report customization.

What users like best:

“The biggest benefit of using Quickbooks Online is its reliability and convenience. By moving to a cloud-based system, clients can easily access their data, whether they are onsite or offsite, and collaborate more efficiently with accountants, suppliers, employees, and more.

Updates come automatically, so users always have the latest version installed without worrying about manual upgrades or downloading outdated software. Its intuitive design makes it easy for even novice users with little accounting knowledge to perform basic functions such as sending invoices and tracking expenses.”

- QuickBooks Online Review, Preston H.

What users dislike:

“I do not like that QuickBooks has long waiting times for customer support. Waiting on hold can be tedious and inconvenient at times. The monthly fee associated with this add-on can be disproportionately high for customers who do not accept credit cards regularly.”

- QuickBooks Online Review, Mary L.

2. Cin7 Core

Cin7 Core is a cloud-based inventory management system designed to help businesses streamline their operations. It offers features like multi-channel sales integration, real-time stock updates, purchase order management, and barcode scanning.

What users like best:

"Cin7 Core effectively connects our website and ordering process to our financial system, QuickBooks. The integrations function seamlessly, enhancing our overall efficiency. Additionally, the updated customer service process is much easier to navigate, allowing us to receive timely assistance when needed. I also appreciate the improvements in communication, which have made our interactions more effective."

- Cin7 Core Review, Amber G.

What users dislike:

"I believe the purchasing department would benefit from a more streamlined system, particularly in managing backorders. Currently, the system does not automatically link back ordered items with products arriving in the warehouse. As a result, I must manually monitor the status of back-ordered products, which can be cumbersome. It would be helpful if CIN7 could automatically fulfill backorders upon product arrival. A comprehensive report that integrates information on sales, products, and suppliers would greatly enhance our efficiency."

- Cin7 Core Review, Rafael E.

3. Xero

Xero plays a supporting role in inventory management. While it's primarily accounting software, it can be integrated with inventory management systems. This integration allows for better financial tracking of inventory purchases, sales, and costs.

What users like best:

"There are many aspects I appreciate, but the best feature is its user-friendly interface, which allows me to complete a significant amount of work in minutes through the rule-making process. The blue and white color scheme is an appealing touch as well. Additionally, it generates a variety of financial reports, including Accounts Payable (AP), Accounts Receivable (AR), and specialized features for 1099 forms, which are incredibly useful for analysis."

- Xero Review, Chandan P.

What users dislike:

"There seems to be a lack of interest in genuinely engaging with and listening to your customers. The recent changes you are promoting lack the essential functionalities present in the current version. For instance, tracked inventory should clearly display the available inventory in quotes and invoicing. Please refrain from implementing unnecessary changes. If something isn’t broken, there’s no need to fix it! These alterations frustrate users and prompt us to consider alternative software options."

- Xero Review, Rachel O.

4. TallyPrime

TallyPrime offers a complete business management system that simplifies various business processes like accounting, inventory management, cost management, payroll, and compliance.

What users like best:

“TallyPrime is a comprehensive software with almost all the features required for business activities regardless of the organization size. Users can easily and effectively do their day-to-day work without thinking much.”

- TallyPrime Review, Amal S.

What users dislike:

“Its limited internationalization, integration with other software, and support for complex accounting processes may not make it the best choice for all businesses.”

- TallyPrime Review, Aman Y.

5. GMDH Streamline

GMDH Streamline can analyze inventory data and make more informed decisions. It uses machine learning algorithms to identify patterns and trends in inventory usage, predict future demand, and optimize stock levels. This can help businesses avoid stockouts or excess inventory.

What users like best:

"I love that this tool has significantly reduced the time required for reporting, contributing to increased revenue and improved sales through its accurate demand forecasts. It is user-friendly and has enhanced our daily workflow, making it easy to navigate. Additionally, we receive ample support from the streamlined tools. This software has become an essential resource that we rely on daily to complete all our required tasks."

- GMDH Streamline Review, Judith M.

What users dislike:

"The system lacks several functionalities and customization options. Some calculations only apply to the current month, which can lead to errors in the results. Additionally, while connecting to the ERP system should be straightforward, we’ve found that it may require more IT knowledge than working with Excel spreadsheets."

- GMDH Streamline Review, Juan A.

Inventory optimization FAQs

If you still have questions about inventory optimization, let’s try to answer them in this section.

Q: What is the difference between inventory optimization and inventory management?

A: Inventory optimization focuses on strategically handling inventory levels to maximize financial output and minimize product and monetary waste. Inventory management is more concerned about everyday operations and setting high productivity and efficiency targets for inventory tasks.

Q: What can inventory optimization do for my small business?

A: Inventory optimization helps small businesses by ensuring product availability, reducing excess stock and costs, and improving supply chain efficiency. It enables better data-driven decisions, boosting competitiveness and profitability.

Q: How can I optimize my inventory?

A: First, take the time to understand your supply chain and inventory operations. Based on your observations, rework demand forecasting, set reorder points, manage safety stock, and use inventory management tools to make the right decisions.

Q: How does inventory optimization software fit into the picture? What are some of its helpful features?

A: Inventory optimization software offers tools and insights that help manage and optimize inventory. Features like real-time inventory tracking, stock history records, inventory planning and forecasting, automated replenishment, and multi-location management are beneficial.

Q: How do I choose the right software for my business?

A: Choosing the right software involves considering factors such as business size, industry needs, integration capabilities, features, and support services. Evaluate your options, request demos, and read user reviews to make an informed decision.

To stock or not to stock

That, indeed, is the question. It becomes even more critical in this dynamic age of rapidly changing consumer preferences, unpredictable market trends, and global supply chain disruptions. But finding an answer on your own with manual and outdated processes can be time-consuming and taxing. Let inventory optimization tools take care of the data and analytics while you focus on growing your business and enhancing customer engagement.

Ready to address the bigger question? Learn more about inventory management and how it can help you truly transform your inventory operations.

This article was originally published in 2023. It has been updated with new information. robust

Harshita Tewari

Harshita is a Content Marketing Specialist at G2. She holds a Master’s degree in Biotechnology and has worked in the sales and marketing sector for food tech and travel startups. Currently, she specializes in writing content for the ERP persona, covering topics like energy management, IP management, process ERP, and vendor management. In her free time, she can be found snuggled up with her pets, writing poetry, or in the middle of a Netflix binge.