Managing your inventory is all the rage right now.

All the cool kids are finding new ways to optimize the inventory process. Whether you decide to count manually or implement a virtual system, it’s important to define the way you manage inventory.

What is inventory management?

Inventory management is the planning and organization of a company’s inventory with the help of advanced and unique management systems.

Choosing the right inventory management system and putting it into practice is not always easy. This is why some companies automate the process by utilizing inventory management software. Inventory management software allows companies to track supply chain management processes, inventory deliveries, sales orders, and purchases in one virtual interface. The software can even help identify inventory issues or discrepancies.

Inventory management vs inventory control

Inventory management and inventory control are a great mother/daughter duo. While inventory management focuses more on the overview of an inventory system and replenishing necessary items, inventory control works more specifically to regulate the number of units in stock. Essentially, inventory management ensures that you have what you need when you need it, and inventory control ensures what you already have is working efficiently for you right now.

Inventory control is usually sorted out before inventory management, like optimizing from the inside out. If you’re starting your inventory management journey from the very beginning, you might want to consider utilizing an all-encompassing tool like warehouse management software to gain visibility into your supply chain management and for warehousing inventory processes as a whole. You can also check out the list of best inventory control software solutions.

Want to learn more about Inventory Management Software? Explore Inventory Management products.

Benefits of inventory management

Inventory management allows you to be one with your inventory. When you have total authority over your inventory, expectations become clearer, and plans run smoother. Let’s explore the benefits of inventory management and why your company will thank you for taking control!

76%

increase in revenue for companies who have invested in inventory management optimization strategies.

Source: Perficient

Increase profits: Knowing how much is expected of you and delivering it makes you generate more cash flow. Simple as that. Inventory management gives you the tools to know exactly how much inventory you have available. Then, you can take that information and compare it to your demand planning predictions to determine just how much you can sell, what you need to prepare, and optimize inventory turnover subsequently.

Improve accuracy: When you check things once or twice, you can’t guarantee complete accuracy. When you continuously monitor and optimize, you create space for more precision in inventory counts and demand forecasting.

Decrease costs: Improving accuracy results in fewer human and technology errors. We all know that time is money, so wasting time fixing inventory mistakes is money straight from your company’s pocket.

Boost customer loyalty: What happens when you’re ready to buy a product, but it says it’s sold out? Do you wait for that specific product to be available, or do you try to find a similar product by a different seller? When you are not optimizing your inventory, you’re losing customers. Inventory management allows you to know exactly how much inventory you have and allocate it appropriately. Keep your customers happy and coming back by retaining item availability and being more reliable than competitors.

Lower risks: Effective inventory management lessens the chances of a product shortage or surplus. When inventory items are being organized effectively, you get the opportunity to buy and sell at the right pace to meet supply and demand, and you reduce your chances of not having enough to satisfy demand or being stuck with dead stock and carrying costs.

Save time: Implementing a good inventory management system helps your company move like a well-oiled machine. Inventory planning means less time spent looking for items or cleaning up messes. No matter which system you choose, you are implementing a method to organize your inventory and your team. With everyone on the same page working toward a goal that has clear objectives, there’s no stopping you!

Types of inventory management systems

Because all inventory is unique, so is its necessary method of management. There are four different inventory management systems that use various tactics to optimize a company’s inventory. Each system has its specific applications, pros and cons, and risks involved, but they’re all capable of taking your inventory management to the next level.

The four types of inventory management systems:

- Perpetual system

- Periodic system

- Barcode system

- Radiofrequency identification (RFID) system

1. Perpetual system

The perpetual system is an inventory management method for continuous inventory management. The amount of inventory is taken in real-time as things are moving in and out. Because of its immediate nature, this system is considered the most favorable by stakeholders, retailers, and business owners.

With this system, up-to-date metrics are available at all times, and adjustments can be made as you approach changes in company goals or inventory issues. This method usually utilizes point-of-sales (POS) systems as an interface for calculating inventory and storing the information. The POS system frees up time and money that may have been allocated to manually entering inventory data.

With that in mind, it’s important to look at the potential downsides to the perpetual system. This system presents some extra inventory costs when it comes to labor. There are setup and training costs incurred when implementing this system to ensure that employees can correctly set up and utilize it. If the training isn’t effective, there are also costs to fix human error mistakes in inventory counts.

2. Periodic system

The periodic system is an inventory management technique of keeping a count of inventory in specific intervals. Instead of keeping ongoing inventory as sales and purchases are made, periodic inventory follows a unique pattern usually centering around a company’s accounting period.

This system doesn’t typically utilize any technology in the counting process; inventory is taken manually. As a result, some find the periodic system more time-consuming and, with manual counting, more predisposed to human error.

The benefits of the periodic system show in the implementation stage. Implementing the periodic system is particularly easy because there is minimal setup involved. Because this system doesn’t require technology, taking inventory is as easy as starting to count. It’s also considered favorable among small businesses, especially those with lower inventory numbers. These businesses will have less chance of human error and lower costs than implementing an entirely virtual inventory system.

3. Barcode system

The barcode system is an inventory management method of updating inventory virtually using barcodes. Companies can use the barcodes to categorize inventory based on organization needs and keep inventory as items are scanned and used. As a result, up-to-date information about inventory levels, manufacturing items, shipping, and packing is refreshed quickly and made available at all times.

In addition, this system is considered a low risk due to the minimal chance of human error when counting manually. The customization of the barcode system is also highly favorable, especially for companies with more extensive product lifecycle portfolios and inventory stock levels. Barcodes can be organized by product, project, demand, location, and more.

The biggest con with the barcode system is actually assigning the barcodes. Printing barcodes and placing them on each item in inventory is highly tedious and time-consuming. Luckily, once that process is completed, a software system can keep inventory tracking from that moment forward. Some companies utilize machine learning with barcode software to keep the uniquely generated barcodes organized virtually.

4. RFID system

The radiofrequency identification (RFID) system is an inventory management technique of using tags placed on different items that produce radio signals carrying information about the product. RFID tags work similarly to barcodes in that they keep a virtual count of inventory items. However, RFID system tags are considered more efficient because they don’t need to be scanned like barcodes.

Because the tags are tracked through radio frequency, they can be moved around an inventory location with little to no effort in tracing them in transit. RFID tags also lessen the risk of human error and the total cost of labor. In this system, employees don’t need to take time counting or scanning items.

The RFID system also presents a few challenges that a company would need to address to use these tags. First, the cost of implementing an RFID system is high. With training employees and getting the entire system installed, it can get pretty expensive to automate the inventory process with RFID. There are also potential security concerns with RFID tags and their radio signals. You would never want your product data getting into the wrong hands.

How to implement an inventory management system

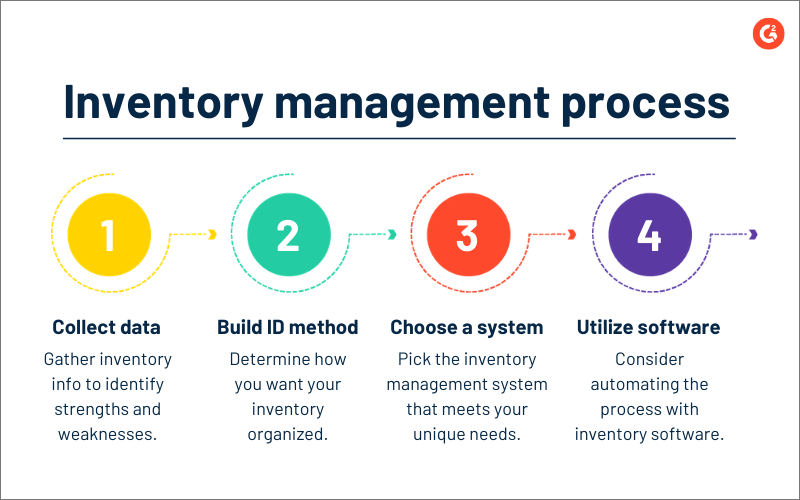

It’s time to put your knowledge into practice. Exploring the inventory systems should have given you a good idea of how you want your inventory process to play out. Ready to start? Follow the steps below to find out what you should do before, during, and after you choose your ideal system.

1. Collect inventory data

Make your inventory process a little bit longer but a lot more efficient by collecting as much data as possible. Data helps companies acknowledge strengths, weaknesses, success patterns, and rooms for improvement. Recognize what inventory needs to be regulated, like raw materials, project supplies, finished goods, and any other physical inventory. This process will create a basis to determine what methods you follow from this step forward.

2. Build an identification method

The next step in managing your inventory is determining how you want your inventory organized. Do you want your items grouped by function? By project? Maybe you want it sorted alphabetically. Create your identification method based on what you think will streamline your process the most when loading and docking shipment goals.

3. Choose a system

After learning about the four inventory management systems, identify the one that aligns with your inventory goals. Looking for a small business-friendly system with little to no technology setup costs? Try the perpetual or periodic system. Hoping to take an automation approach using a virtual organization tool? The barcode or RFID system might be a better fit for you. Use the inventory goals you defined earlier to determine which system meets your company’s needs.

4. Consider utilizing a software system

When in doubt, consider putting your trust in artificial intelligence. Inventory software can help you identify inventory issues before you even notice there were any issues to begin with. The software also offers a helpful interface for quickly updating data and keeping information accurate.

Inventory management techniques

While simply implementing an automated system sounds easy enough, there are a couple of things you can do to make the process even more efficient. Check out some techniques to make inventory management work for you.

Create inventory KPIs

Company key performance indicators (KPIs) apply to every aspect of a business, including inventory. Identify inventory goals and objectives. Those goals may be items of a specific monetary value or product quantity. Recognizing these KPIs will help you determine which inventory takes priority over others.

Forecast demand

As stated earlier, predicting customer demand is the key to knowing just how much inventory is needed at any given moment. When you know how much is required, you know when you’re reaching the reorder point and when you may need to restock. Consider utilizing demand planning software to start predicting customer needs and keep collecting information in the future to continue forecasting future demand and adjusting inventory and pricing.

Continue replenishing items as they are used

If ordering as you go sounds like a fit for you, consider trying the just-in-time (JIT) inventory management method. Depending on demand, you may need to consider replacing inventory items before they get too low. Utilize your proposed inventory quotas and the management system of your choice to identify what “too low” is for you. With the JIT method, ordering stock can be done on an as-needed basis or on a predetermined schedule based on inventory historical data. Doing this can help you get a step ahead in fulfilling demand purchase orders and accumulating the right amount of items before it gets overwhelming.

Conduct regular quality control checks

Your management is only as good as your finished products are. Conducting routine quality analyses will put you on the right track to deliver the best versions of your new products, ensuring you aren’t holding onto items that aren’t needed and spending extra money on the cost of goods. Inventory means nothing if your stock is bad!

Utilize an EOQ model

An economic order quantity (EOQ) is the ideal quantity of items a company should order to ensure they do not experience a shortage or surplus. You can calculate your EOQ by gathering data on customer demand, setup costs, and holding costs.

Economic order quantity (EOQ) formula:

EOQ = √ (2DS/H)

D → demand

S → setup costs

H → holding costs

Setup costs would include costs of packing, shipping, delivery, etc. Holding costs would consist of any additional costs associated with inventory warehousing, insurance, and storage. After multiplying the demand units and the setup costs by 2, divide by the holding costs, and take the square root of the final number. In the end, you will be left with an EOQ that will guide you towards minimizing costs and meeting expected demand.

Organize items by importance

Identify what items take precedence over others and which should never run out. If you’re selling perishable products, you may consider a first-in first-out method (FIFO) method when sending out items. If you’re selling nonperishables, you may want to opt for a last-in first-out (LIFO) method to avoid disrupting established inventory. If those don’t seem ideal for you, try the ABC analysis method. With ABC analysis, you would categorize your inventory stock into three tiers of importance, from A to C. Choose the method that makes the most sense and regulate new inventory accordingly.

Resume taking inventory during transit

When things are constantly moving, it can be easy to lose track of items in the process. Avoid only taking inventory at your primary inventory location. Make it a point to keep counting at every step of your inventory management process, wherever it may take you.

Inventory control software

Looking to implement some inventory management features into your inventory process? Consider using inventory control software to automate the process. Inventory control software offers a little bit of everything you need to create a lean, mean inventory machine.

To be included in this category, the software product must:

- Use technology to track inventory flow

- Include a comprehensive inventory database

- Offer tools to predict future inventory

*Below are the top 5 leading Inventory Control software solutions from G2’s Summer 2021 Grid® Report. Some reviews may be edited for clarity.

1. QuickBooks Online

Organize your inventory finances in one platform with QuickBooks Online. QuickBooks Online offers the ability to invoice and accept payments, forecast cash flow, and access real-time analytics.

What users like:

"Without any doubt, QuickBooks Online is a great software that was launched with an aim to help small and medium-sized businesses maintain their accounts. It has a very user-friendly interface, especially the dashboard. When it comes to the reporting section, Quickbooks Online comes with the ability to generate important management reports. For instance, whether you need a report of trial balance, receivables, or payables, you can easily make it in Quickbooks Online. Furthermore, as it is a cloud-based app, you can access it instantly from anywhere in the world if you have an internet connection."

- QuickBooks Online Review, Rajesh C.

What users dislike:

"I dislike the cost and the fact that you must pay a subscription plan for each individual business. This can be tough for smaller businesses just starting out. When compared to the desktop version, it is a one-time fee and the desktop version can host multiple businesses. To try to manage these costs, we have moved some of our QBO instances onto the desktop version run by our accountant. QBO cloud features are not all necessary for standard accounting. So if you need simple accounting, I would stick to the desktop version, or better yet, try to use the desktop version and let your accountant manage it."

- QuickBooks Online Review, Steven F.

2. Zoho Inventory

Zoho Inventory is a cloud-based software used to track purchases, inventory, and sales channels. With Zoho Inventory, expect to get up-to-date insights into your inventory management systems and sales processes.

What users like:

“Zoho Inventory is the software most used not only by me but by the company where I work since it allows us to organize the inventory of our food and beverage warehouses. With this software, I can organize the inventory, the orders, the sales, and the merchandise shipments; that is to say, I can manage all the activities associated with the inventory of my company. All the procedures are fulfilled efficiently without losing the detail of entrance and exit of the products of our warehouses.”

- Zoho Inventory Review, Debora C.

What users dislike:

“There are a few downfalls - the back-end seems to be locked down, meaning there are some changes or customizations that cannot be made, no matter how important. The connectivity between Inventory and CRM is also limited.”

- Zoho Inventory Review, Jazmine D.

3. Webgility

Stop overselling with Webgility. Webgility gives you the tools to automatically update inventory, track orders, and keep accurate counts.

What users like:

“After researching several software, we chose Webgility due to the excellent support they provide. It was super important for us to have after-sale support, as software is constantly changing. The support team has always helped us resolve issues promptly. The integration and setup were very easy compared to other software we've used, and Webgility was helpful every step of the way.”

- Webgility Review, Janna R.

What users dislike:

“There are no notifications when Webgility needs to be updated to the newest version. When this happens, the software gets buggy, and we seem to always be reactive to this issue rather than proactive if there was some sort of notification system in place. Sometimes the platform can be buggy, but most of the time it can be fixed.”

- Webgility Review, Corey V.

4. NETSTOCK

NETSTOCK is a cloud-based inventory management optimization solution. The NETSTOCK dashboard helps to minimize shortages and surpluses, track inventory targets, and gather KPI information over time.

What users like:

"With NETSTOCK, we achieved a 50% reduction in stock-holding and a 15% fill rate improvement. Their simple dashboard gives insight into important metrics and allows, with a few clicks, to drill into more detail. The integration with our ERP was relatively simple and NETSTOCK unquestionably receives 10 stars for the fantastic customer service!"

- NETSTOCK Review, Luisa T.

What users dislike:

"No real negatives to date but the quicker you learn how NETSTOCK calculates using the different algorithm, the quicker you will understand how it formulates the information on display."

- NETSTOCK Review, Alan P.

5. Kintone

Kintone offers pre-built inventory management applications to track data effortlessly. It prides itself for being easily customizable and user-friendly.

What users like:

“We've been with Kintone for about a year, and it's been a pretty good experience. We've been able to create some simple apps quickly and painlessly without the need for development skills. However, with our team's development skills, we've also been able to create much more complex production management software that connects multiple apps together. Everything is adaptable, and thus we keep building on it as our business grows.”

- Kintone Review, Drew M.

What users dislike:

“The portal customization tool is great; however, it could use more robust features and native functionality. As different departments in a business have different types of responsibilities and need to see different datasets quickly. For example, if the sales managers wanted to see their sales reps, sales, leads, funnels, it would be great to be able to access reports and data based on the log in all from a centralized dashboard.”

- Kintone Review, Christopher M.

If your friends started managing their inventory, would you?

If you have inventory, you have everything you need to start the journey toward implementing an inventory management system. Whether you plan to automate the process or get things done the old-fashioned way, organizing your inventory and optimizing for the future only benefit you along the way. I don’t mean to peer pressure you, but inventory management really is the (not-so-new) hot thing.

After all, the cool kids are doing it!

Ready to start streamlining your company’s inventory process? Find out how inventory management can benefit a retail business in the e-commerce space!

Alexandra Vazquez

Alexandra Vazquez is a Senior Content Marketing Specialist at G2. She received her Business Administration degree from Florida International University and is a published playwright. Alexandra's expertise lies in copywriting for the G2 Tea newsletter, interviewing experts in the Industry Insights blog and video series, and leading our internal thought leadership blog series, G2 Voices. In her spare time, she enjoys collecting board games, playing karaoke, and watching trashy reality TV.