Manufacturing processes are complex and require multiple tools to achieve the desired results. Certain tools used in the manufacturing sector, such as product lifecycle management (PLM), enterprise resource planning (ERP), and quality management systems (QMS), have unique, but complementary features. At present, companies are looking to combine such software tools to have better visibility into their manufacturing operations. However, it is important that the integration is done in an appropriate manner, or else it fails to maximize the organization’s efficiency.

What are PLM, ERP, and QMS Software?

PLM, ERP, and QMS software offer a host of benefits to manufacturing companies. A PLM solution assists in managing product information across all stages of product development. An ERP system aids in the efficient management of core business processes such as finance, manufacturing, supply chain, procurement, and others. QMS software helps companies analyze and maintain the quality of produced goods and manage customer experiences.

Individually, these tools support manufacturing operations. However, their integration can work wonders for manufacturing companies. In this article, we will explore the advantages of using the right mix of these tools and the problems this approach can solve.

What do ERP, PLM, and QMS have in common?

All these solutions focus on manufacturing with features (and sometimes separate solutions) for each main manufacturing type: discrete, process, and engineer-to-order (ETO).

| Related: How to Determine the Software You Need for Manufacturing → |

Discrete manufacturing deals with the production of discrete or separate units. Examples of goods made through the discrete manufacturing process include component parts such as nuts, bolts, wires, and assemblies. It can also be used to produce finished goods such as vehicles, airplanes, furniture, computers, smartphones, and more.

Process manufacturing is used for producing goods in bulk quantities. This method applies specific techniques and formulas to produce goods and automate tasks. Examples of goods produced by process manufacturing include food and beverages, paint, pharmaceuticals, and refined oil.

Under the ETO process, companies design and manufacture products based on specifications provided by the customer. ETO is typically used for creating sophisticated and unique products such as custom-engineered satellites, avionics, and more.

Vendors tend to focus on one or two manufacturing types, and occasionally on industries like fashion and apparel or food and beverage. Specialization in manufacturing software is logical since only some vendors can afford to invest in buying and developing software for multiple industries.

Who needs to combine manufacturing software, and how?

PLM and QMS are two distinct solutions used by different departments. PLM, ERP, and QMS solutions are complementary to each other but are typically implemented either in silos or with little integration. Lack of proper integration leads to poor communication and poor quality of products. This happens due to the low visibility of information available to the design and product teams.

| TIP: Connecting PLM, ERP, and QMS allows companies to streamline workflows, achieve higher visibility of product-related information, reduce errors, save costs, and enhance productivity. |

Nevertheless, finding the right mix of PLM, ERP, and QMS solutions is difficult. Firstly, the features required can vary significantly by industry and company size. Also, these features can be delivered as part of one or multiple systems, provided by the same vendor or multiple ones.

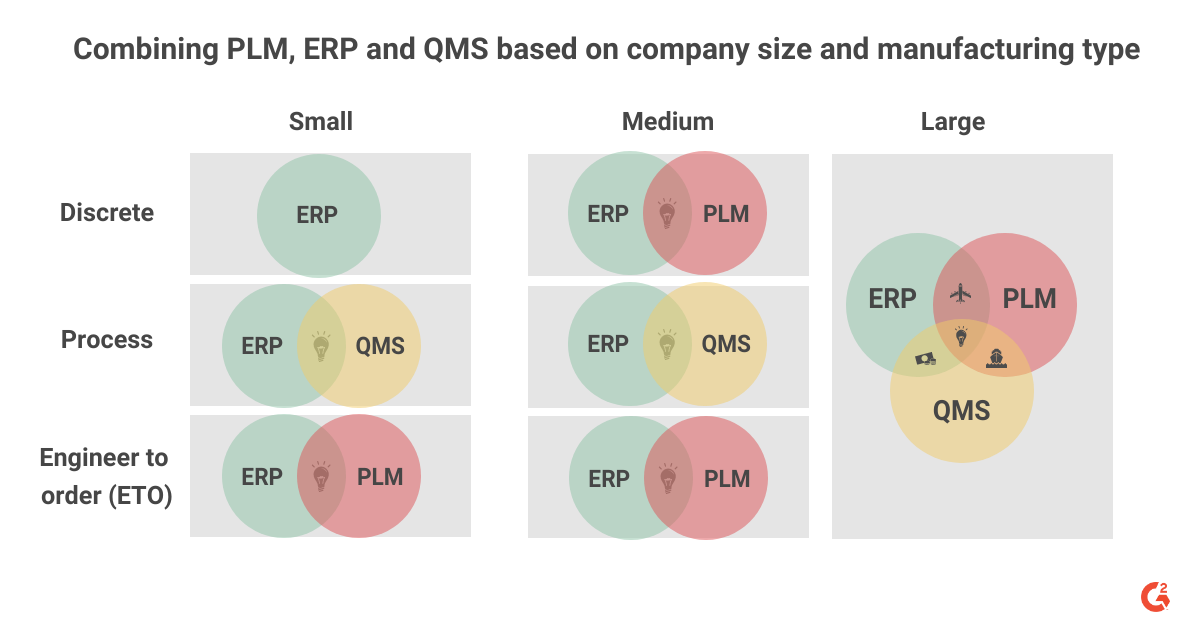

The image below describes a high-level overview of different combinations of manufacturing solutions by industry and company size. As a rule, the larger the company and the more complex its operations, the more complicated the software mix.

As shown below, small discrete manufacturers may only need ERP, while large companies will need all three systems, no matter what they manufacture. There are many exceptions to this, though. For instance, a medium aerospace and defense manufacturer is likelier to use all three solutions than a large fashion and apparel company that outsources parts of its operations, such as design or production.

Note: This information should be used as a starting point by companies looking for manufacturing software, but not as an ultimate recipe for selection success. While the third column shows the same mix of products, the features of each solution and how they're integrated can be significantly different when comparing different combinations of ERP, QMS, and PLM.

Easier said than done: factors to account for while combining complex manufacturing software.

In theory, all of these solutions can be integrated, but there are a few things buyers should consider when choosing the optimal combination of solutions.

An ERP-PLM-QMS integration offers enhanced inter-department communication and high visibility across the product lifecycle and production. However, with a lack of know-how of factors to consider while selecting the right mix, an organization may end up with a solution that does not serve the requirements.

What factors should be taken into account while integrating these tools?

- Selecting the right vendor based on software functionalities: ERP vendors may sell PLM and QMS software, but these aren't always the best solutions in the market. It may be preferable to buy the latter from other vendors that offer more robust functionality.

- Partnership with the vendor: Vendor partnerships provide tighter integration, which makes data transfer between systems more manageable. At the same time, buyers have limited options since not all vendors have partnerships. It is crucial to select an implementation partner who has the required knowledge and expertise to integrate the solutions.

- Selecting solutions depending on the requirements of the organization: Some ERP products may include features for PLM and QMS. This type of software is preferable for SMBs since it's more affordable and easier to manage one system instead of two or more. PLM may not be required for basic design needs, and computer-aided design (CAD) tools can replace it.

- Selecting a vertical-based solution: Vertical focus is essential because ERP, PLM, and QMS solutions don't usually cover all sectors. Therefore, finding the right product mix for each industry is vital. For instance, there are ERP and PLM solutions specializing in fashion and apparel or QMS solutions focusing exclusively on life sciences.

.png)

Source: G2 Reviews for PLM, ERP, and QMS software

Integration can drive optimal use of software solutions

There’s no denying that PLM, QMS, and ERP have different purposes to serve. However, their capabilities overlap in ways that can impact the entire manufacturing process. Efforts for driving digital transformation are inducing organizations to make optimum use of their existing solutions. Instead of purchasing add-on software solutions separately, it is imperative to find ways to integrate existing solutions to detect product quality issues on time, improve communication between cross-functional teams, and drive growth.

This article is co-written by Anindita Sengupta, G2 research analyst, cloud infrastructure, web hosting, CAD & PLM

This article is co-written by Anindita Sengupta, G2 research analyst, cloud infrastructure, web hosting, CAD & PLM

Edited by Sinchana Mistry

Want to learn more about Product Lifecycle Management (PLM) Software? Explore Product Lifecycle Management (PLM) products.

Gabriel Gheorghiu

Gabriel’s background includes more than 15 years of experience in all aspects of business software selection and implementation. His research work has involved detailed functional analyses of software vendors from various areas such as ERP, CRM, and HCM. Gheorghiu holds a Bachelor of Arts in business administration from the Academy of Economic Studies in Bucharest (Romania), and a master's degree in territorial project management from Université Paris XII Val de Marne (France).