From the mobile phone to the personal computer, there have been numerous times in human history when a piece of technology has completely transformed society. Now is one of those times.

While it’s gone through major changes throughout its 30-plus years of existence, 3D printing is a technology capable of not only transforming society but doing so in a positive way.

When 3D printing first gained popularity in 2010, it was touted as technology for the consumer. Every house would own a 3D printer capable of printing everything from food to clothes for the personal user. The reality is that 3D printing has evolved into something much more dynamic.

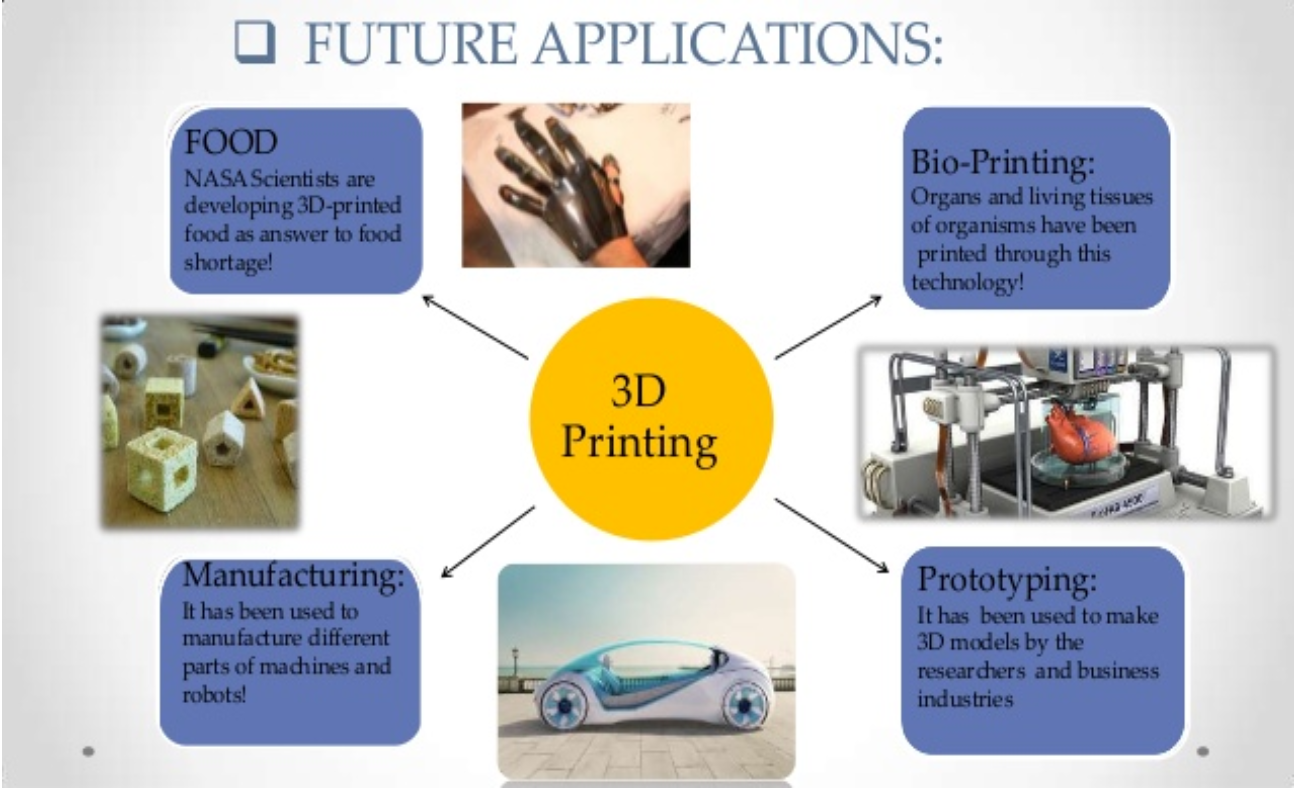

Instead of serving the consumer, 3D printing has served the common good in ways most people wouldn’t have fathomed when the technology was introduced. From bringing patients cheaper health care to building homes for the homeless, the possible uses of 3D printing are now endless. Below are some of the key trends in 3D printing and how they might pave the way to advancement in various fields.

Source: XYZ printing forum

Reducing the cost of prosthetics

Prosthetics manufacturer Mercuris has stated that by combining 3D printing software with 3D modeling software, the company has reduced prosthetic limb production costs by 75%. With product options offered for as low as $50, 3D printing provides inexpensive prosthetics for families that may not otherwise be able to afford these necessities. For children needing prosthetics that adapt as they grow, 3D printing is a great alternative to shelling out thousands of dollars every odd year on a new prosthetic arm.

With the field a work in progress, the best news about 3D-printed prosthetics is that they constantly improve. More and more 3D printers are becoming compatible with more durable materials. This will help 3D-printed prosthetics stay affordable and last longer.

Organ engineering

One of the most exciting advancements in modern health care is bioprinting. Bioprinting is an extension of traditional 3D printing in which users produce living tissue, bone, blood vessels, and, potentially, entire organs for use in medical procedures. Bioprinters operate the same as 3D printers, except instead of printing hard materials like ceramic, they deposit layers of biomaterial soft enough to replicate tissue or blood vessels.

Recent experiments at Rice University have produced a 3D bioprinter that can print vessels less than a third of a millimeter wide in biocompatible hydrogels. The experiment resulted in a team of researchers creating a model of a human lung that can oxygenate blood. This experimentation employed a 3D bioprinting method called stereolithography. In addition to bioprinting human lungs, experiments have been conducted in which researchers successfully bio-printed bones, human skin, cartilage, and blood vessels.

Although each experiment is an exciting step in the right direction, researchers say they still have a long way to go before they 3D print a functioning organ for human transplant. It should go without saying that modeling the cellular complexities of the human body may take years of testing before methods are perfected and receive regulatory approval.

Even so, according to Grand View Research, the 3D bioprinting market will reach $4.1 billion by 2026, which represents a major increase in the sector. With this in mind, it’s exciting to live in a time when technological advancements can help those in need.

3D printed homes

Recently, construction company ICON built an 800-square-foot house using the futuristic Vulcan II 3D printer. If you don’t think it’s impressive that a piece of technology printed an entire house, consider that it took less than 24 hours and cost only $10,000.

A survey by the National Association of Home Builders found the average cost per square foot to build a home using traditional methods is around $85.65. This means constructing an 800-square-foot house costs, on average, around $68,000. ICON’s 3D-printed house cost six times less money and took only 24 hours to build.

If that isn’t revolutionary enough, the firm claims this is simply one of the first steps in 3D printing homes. ICON predicts it can 3D print 2,000-square-foot homes for between $4,000 and $6,000.

ICON plans to partner with New Story, a San Francisco nonprofit organization, to print 100 homes in El Salvador. The goal of the partnership is to combat homelessness and offer an accessible and affordable option for lower-class families across the world.

The good news is it’s not just one company embracing the idea of 3D-printed homes. All across the world, countries are recognizing that 3D-printed homes can combat homelessness and poverty. In 2016, the vice president and prime minister of the United Arab Emirates (UAE) and the crown prince of Dubai said that by 2030, around 25% of Dubai’s buildings will be 3D printed. This initiative shows the confidence UAE has that 3D-printed homes can have a great impact on a country’s housing sector.

3D printing makes the world more environmentally-friendly

3D printing is an environmentally-friendly alternative to traditional manufacturing: 3D printing uses biodegradable materials, rarely wastes materials and most materials that are used are recyclable. While 3D printing uses a considerable amount of electricity, it also reduces the carbon footprint manufacturing leaves on the environment.

Using recycled plastic in 3D printing to reduce ocean waste

One of the most innovative sustainability initiatives businesses are implementing involves the transformation of plastic waste and pollution into 3D-printed filament.

Adidas and marine environmental organization Parley for the Oceans recently announced an initiative to turn plastic waste into athletic shoes. These businesses took plastic waste from the ocean that negatively impacted marine life in the Maldives and successfully used it to produce shoes.

Two years later, Adidas announced “FUTURECRAFT.LOOP.” With this initiative, the company aims to reduce ocean waste by transforming plastic from beaches and coastal communities into 3D printable polymers. These polymers can also be used in 3D printing to create athletic shoes.

Source: Adidas

Source: Adidas

In even better news, Adidas plans to use this 3D printing method on all of its products by 2024.

Using 3D printing to restore decaying coral reefs

According to research, more than 50% of the world’s coral reefs have died in the last 30 years, and up to 90% may die within the next century. Bleaching, which makes reefs more susceptible to disease, occurs due to rising ocean temperatures, pollution, and overexposure to sunlight. Without reefs, marine life cannot thrive.

The good news is that design labs have found a way to use 3D printing to create artificial reefs. In 2012, one of the first 3D-printed reefs was placed in Reef Arabia, a reef off the coast of Bahrain. Over time, marine life flocked to the reef, and it became abundant with biodiversity.

Developments in bioprinting have made it possible to 3D print massive coral reefs. Recently, a large 3D-printed coral reef was placed in the Maldives, as seen in the video below.

While 3D printing might not offer a permanent solution to fix the coral reefs, it offers a temporary recovery plan for some marine life that might not otherwise thrive. The hope is these artificial reefs attract coral larvae that will encourage actual coral reefs to reproduce in these areas.

Businesses of all kinds are embracing 3D printing software

Aside from positively impacting the environment and the healthcare industry, everyday businesses use 3D printing for product prototyping in engineering and manufacturing.

According to a survey by Jabil, over the next two to five years, 86% of companies expect their use of 3D printing to at least double, and 39% of companies stated they expect their usage to increase five times or more. This is because businesses are realizing that 3D printing can cut production costs and save time by expediting the manufacturing process.

Learn more about 3D printing - its history, types, applications, and how it streamlines prototyping and production.

Michael Gigante

Mike is a former market research analyst focusing on CAD, PLM, and supply chain software. Since joining G2 in October 2018, Mike has grounded his work in the industrial and architectural design space by gaining market knowledge in building information modeling, computer-aided engineering and manufacturing, and product and machine design. Mike leverages his knowledge of the CAD market to accurately represent the space for buyers, build out new software categories on G2, and provide consumers with data-driven content and research. Mike is a Chicago native. In his spare time he enjoys going to improv shows, watching sports, and reading Wikipedia pages on virtually any subject.