In June 2021, I wrote an article that described how cloud enterprise resource planning (ERP) can help solve manufacturing challenges and highlighted integrated systems as the main benefit of software as a service (SaaS) ERP systems.

This is particularly important for production operations which require and generate data that impacts most (if not all) departments of a manufacturer. A few examples are sales data such as quantities ordered by customers and the cost of raw materials, components, and labor required to manufacture a product.

Using all this information, the production department needs to allocate resources to manufacture products and ensure that they are delivered on time and at the correct cost. This post, which is the second in a series of blog posts, will describe how production departments can use cloud ERP to plan and improve resource management.

The critical role of resource management in manufacturing

Post resource allocation, the next step is to plan production operations based on resource availability and estimated times of delivery. Finally, production plans are implemented on the shop floor, and procedures are monitored to avoid quality issues such as defects and bottlenecks that may cause delays.

If there are discrepancies between what customers expect and what they get, manufacturers may need to pay penalties, replace or reship products, and even lose customers. It is, therefore, safe to say that the fate of a manufacturing company is in the hands of the production department.

What is manufacturing resource planning (MRP)?

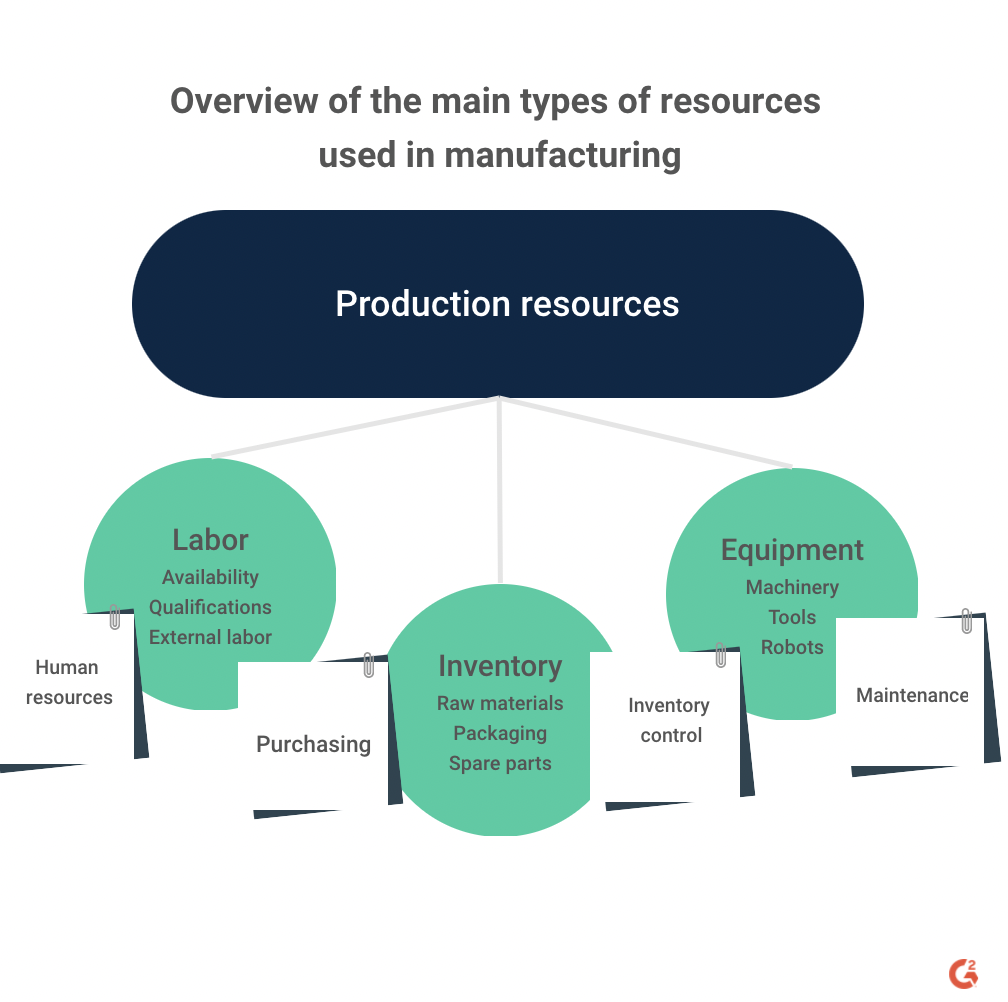

Manufacturers require three main categories of resources for production: labor, inventory, and equipment. Depending on the complexity of the product being manufactured, each of these categories can have multiple levels of subcategories for particular needs. One example is labor, which can be internal (provided by the company's employees) and external (outsourced to third-party companies). The ERP functionality for resource management is referred to as manufacturing resource planning (MRP).

Resource management in manufacturing provides the following benefits to manufacturers:

- Improve resource availability for production, by tracking detailed information on what components or raw materials are missing and need to be bought or replaced.

For example, an apparel manufacturer running out of a specific type of fabric may replace it with a similar one, as long as the two are compatible.

- Optimize the cost of the resources used for production, which can impact the profitability of the company.

In the example above, replacing fabric may be more expensive than the original, which increases the total cost of the product and decreases the profit. - Better visibility into changes that may impact resource availability across the company and its supply chain.

For instance, if the fashion manufacturer mentioned above cannot replace a missing fabric, they will need to order it, most likely from overseas suppliers. If suppliers face any disruptions in their operations, the buyer and its production plans will also be affected.

Why cloud ERP is better for manufacturing resource management

Cloud ERP delivers the benefits mentioned above in several ways:

- Cloud ERP helps provide a holistic view of the manufacturing process which improves visibility into resource availability and identifies bottlenecks. For instance, a piece of equipment may be reassigned to prioritize an order for an important customer. If this change isn't reflected in the resource management database, salespeople will think that the equipment is still assigned to the initial production cycle.

- The cloud makes it easier to gather information from multiple sources and update the data in near real time. This improves the accuracy of MRP calculations and helps with decision making, mainly when changes occur frequently. An example of this is the fast-moving consumer goods (FMCG) industry, which focuses on products of low value that are sold quickly. Fast-moving also means that manufacturers need to adapt rapidly to market changes. The food and beverage industry is an excellent example since demand can vary significantly by season, such as spring or summer versus winter holidays.

- Cloud ERP is easier to use on mobile devices, thus allowing employees to access critical resource information wherever they are (in the field, warehouse, or production facility). In addition, cloud ERP is usually web responsive (the interface resizes based on the display of a mobile device), and most providers also offer mobile native apps (specifically designed for mobile operating systems such as iOS and Android).

| Related: How Cloud ERP Helps Address Manufacturing Challenges → |

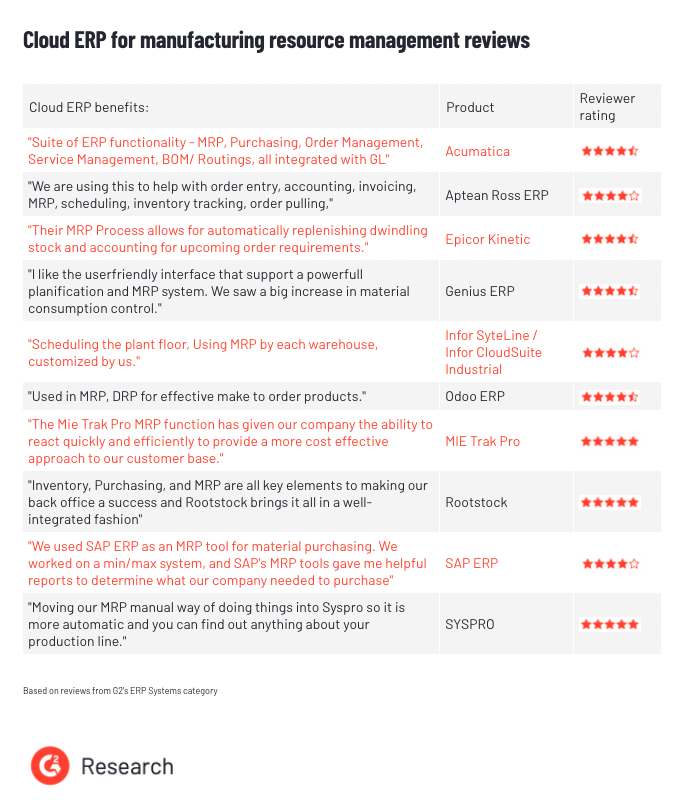

Some of the benefits of cloud ERP for resource management mentioned by G2 reviewers are listed below:

TIP: ERP doesn't always include features to manage all types of resources required in the manufacturing business. Human resources (HR) and workforce management solutions focus on employee scheduling, while computerized maintenance management systems (CMMS) and enterprise asset management (EAM) are used for asset management. Therefore, it is essential to integrate all these systems to get a complete picture of all resources and their availability.

Next step: production planning

My next blog post will describe how cloud ERP helps manufacturers with production planning and control, including resource allocation, work order scheduling, and production monitoring.

Want to learn more about ERP Software? Explore ERP products.

Gabriel Gheorghiu

Gabriel’s background includes more than 15 years of experience in all aspects of business software selection and implementation. His research work has involved detailed functional analyses of software vendors from various areas such as ERP, CRM, and HCM. Gheorghiu holds a Bachelor of Arts in business administration from the Academy of Economic Studies in Bucharest (Romania), and a master's degree in territorial project management from Université Paris XII Val de Marne (France).